Filter Technology Offers

Featured

Category

Topic

- Electronics, IT and Telecomms

- Industrial manufacturing, Material and Transport Technologies

- Design and Modelling / Prototypes

- Industrial Manufacture

- Process control and logistics

- Plant Design and Maintenance

- Packaging / Handling

- Construction Technology

- Materials Technology

- Transport Infrastructure

- Transport and Shipping Technologies

- Aerospace Technology

- Traffic, mobility

- Industrial Technologies

- Energy Technology

- Physical Sciences and Exact Sciences

- Biological Sciences

- Agriculture and Marine Resources

- Agrofood Industry

- Measurements and Standards

- Protecting Man and Environment

- Social and Economics concerns

- Lightweight

- Sustainability

- Digitalization

- Opthalmology

- Aerospace

- Communications

- Computer related

- Electronics Related Market

- Genetic Engineering / Molecular Biology

- Medical Health related

- Energy Market

- Consumer related

- Industrial Products

- Other

Country

Showing all visible results for Industrial manufacturing, Material and Transport Technologies

University of Girona (OTRiT)

12 Followers

9 publications

University of Girona (OTRiT) posted this:

12 Followers

Innovative Products and Technologies

- +2 weeks

- Hide post

University of Girona (OTRiT)

12 Followers

9 publications

University of Girona (OTRiT) posted this:

12 Followers

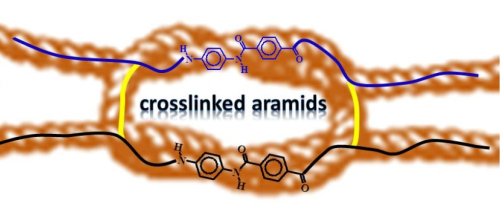

Method to taylor the residual stress state in fiber reinforced stress-relaxable polymers

Innovative Products and Technologies

- +3 weeks

- Hide post

Flash-Thermography: High-Speed non-invasive sexing via differential wing insulation

Innovative Products and Technologies

- +1 month

- Hide post

Pumice-Based Nanofiber Technology for Ultra-Lightweight, Fire-Resistant and Scalable Industrial Applications

Innovative Products and Technologies

- +1 month

- Hide post

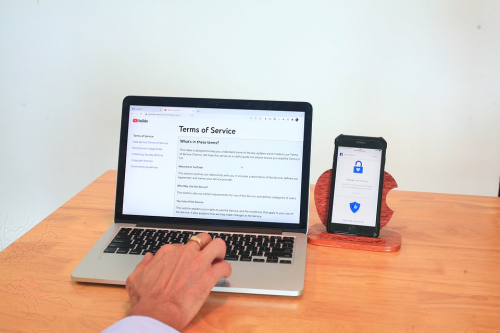

Market research, consumer studies and advice for the development of online and mobile commerce

Innovative Products and Technologies

- +1 month

- Hide post

Manufacture of an eco-cobble from recycled material

Innovative Products and Technologies

- +1 month

- Hide post

Sustainable gypsum prefabricated from polyurethane foam residue

Innovative Products and Technologies

- +1 month

- Hide post

Material capable of detecting the decomposition of certain packaged foods.

Innovative Products and Technologies

- +1 month

- Hide post

Max-Planck-Innovation GmbH

0 Followers

13 publications

Max-Planck-Innovation GmbH posted this:

0 Followers

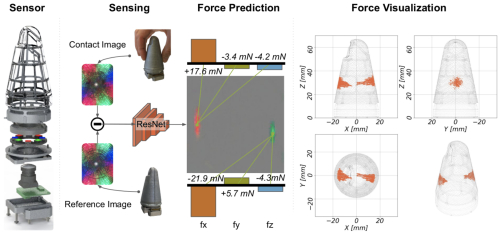

Insight: Haptic Sensor with Camera and Machine Learning

Innovative Products and Technologies

- +2 months

- Hide post

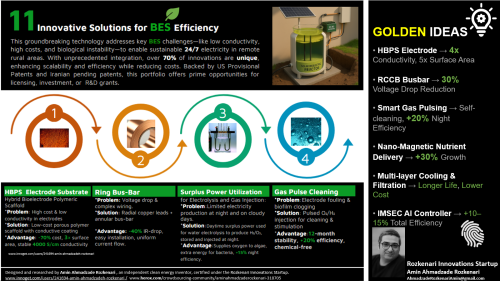

Amin Ahmadzadeh Rozkenari

0 Followers

2 publications

Amin Ahmadzadeh Rozkenari posted this:

0 Followers

11 Innovative Solutions to Boost Efficiency & Stability in Bioelectrochemical Reactors

Innovative Products and Technologies

- +5 months

- Hide post

Amin Ahmadzadeh Rozkenari

0 Followers

2 publications

Amin Ahmadzadeh Rozkenari posted this:

0 Followers

Patented Bioelectrode (HBPS) & Current Collection System (RCCB) – Solutions #1 & #2

Innovative Products and Technologies

- +5 months

- Hide post

CUO/TIO2 polymeric nanocomposites with improved NIR reflectance for coloured external wall finishing coatings of buildings

Innovative Products and Technologies

- +5 months

- Hide post

- 1

- 2