Filter Technology Offers

Featured

Category

Topic

- Electronics, IT and Telecomms

- Industrial manufacturing, Material and Transport Technologies

- Industrial Technologies

- Energy Technology

- Physical Sciences and Exact Sciences

- Biological Sciences

- Agriculture and Marine Resources

- Agrofood Industry

- Measurements and Standards

- Protecting Man and Environment

- Social and Economics concerns

- Lightweight

- Sustainability

- Digitalization

- Opthalmology

- Aerospace

- Communications

- Computer related

- Electronics Related Market

- Genetic Engineering / Molecular Biology

- Medical Health related

- Energy Market

- Oil and Gas Exploration and Production

- Oil and Gas Drilling, Exploration and Extraction Equipment

- Alternative Energy

- Coal Related

- Energy Conservation Related

- Other Energy

- Power generation

- Enhanced Oil Recovery (EOI)

- Energy Supply and Retail

- Energy Distribution

- Energy Storage

- Energy for Transport

- Consumer related

- Industrial Products

- Other

Country

Showing all visible results for Energy Market

Patents for licensing

- +2 weeks

- Hide post

Carbon Paste innovative formulation for photovoltaics and printed electronics

Innovative Products and Technologies

- +1 month

- Hide post

Amin Ahmadzadeh Rozkenari

0 Followers

2 publications

Amin Ahmadzadeh Rozkenari posted this:

0 Followers

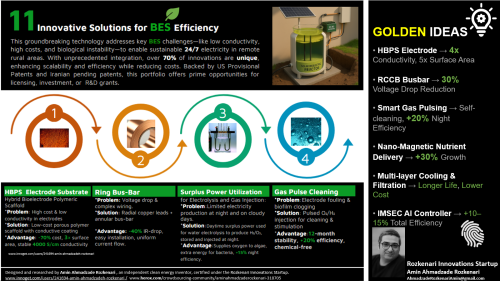

11 Innovative Solutions to Boost Efficiency & Stability in Bioelectrochemical Reactors

Innovative Products and Technologies

- +5 months

- Hide post

Amin Ahmadzadeh Rozkenari

0 Followers

2 publications

Amin Ahmadzadeh Rozkenari posted this:

0 Followers

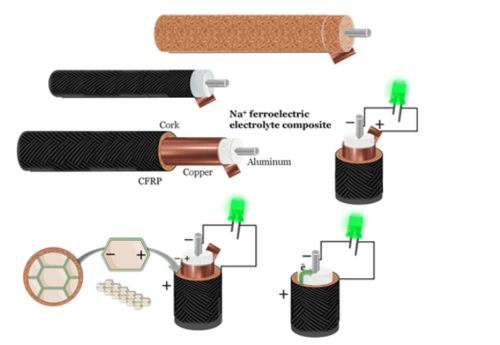

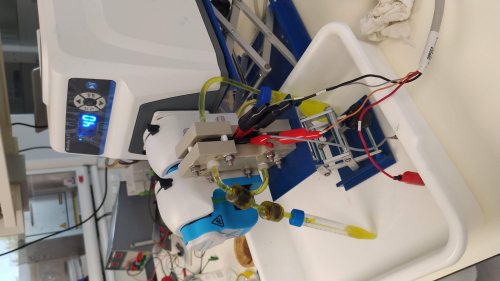

Patented Bioelectrode (HBPS) & Current Collection System (RCCB) – Solutions #1 & #2

Innovative Products and Technologies

- +5 months

- Hide post

Grease Trap Saver: Retrofit Technology for Fuel-Grade Grease Recover

Innovative Products and Technologies

- +6 months

- Hide post

Clean technology for the efficient recovery of cathodes in lithium batteries

Patents for licensing

- +6 months

- Hide post

Microgrid Connector Controller (MGC): an effective controllable grid interface for microgrids

Innovative Products and Technologies

- +6 months

- Hide post