Filter Technology Offers

Featured

Category

Topic

- All categories

- Protecting Man and Environment

- Safety

- Environment

- Ecology

- Environmental Engineering / Technology

- Measurement and Detection of Pollution

- Natural Disasters

- Remote sensing technology

- Biodiversity / Natural Heritage

- Noise Pollution

- Capture and Storage of CO2

- Climate Change mitigation

- Soil and Groundwater Pollution

- Clean Production / Green Technologies

- Life Cycle Assessment

- Outoor Air Pollution/Treatment

- Indoor Air Pollution/Treatment

- Remediation of Contaminated Sites

- Waste Management

- Water Management

- Communications

- Computer related

- Electronics Related Market

- Genetic Engineering / Molecular Biology

- Medical Health related

- Energy Market

- Consumer related

- Industrial Products

- Other

Country

Showing all visible results for Environment

Patents for licensing

- +1 month

- Hide post

University of Girona (OTRiT)

13 Followers

9 publications

University of Girona (OTRiT) posted this:

13 Followers

MICROconcentrator of Carbon Dioxide (CO₂) in INdoor Environments (MICRO-IN)

Innovative Products and Technologies

- +1 month

- Hide post

University of Girona (OTRiT)

13 Followers

9 publications

University of Girona (OTRiT) posted this:

13 Followers

Predictive modelling of air pollution and other meteorological variables

Innovative Products and Technologies

- +1 month

- Hide post

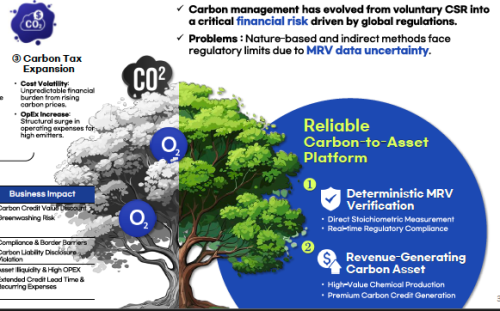

A Deterministic CO₂-to-CO Conversion Platform Enabling Reliable, Auditable, and Asset-Grade Carbon Utilization.

Patents for licensing

- +1 month

- Hide post

Smart Heat Management with Core-Shell Catalyst Pellets: Preventing Hotspots, Maximizing Yield

Patents for licensing

- +4 months

- Hide post

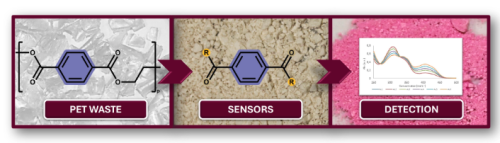

GREENPET: sustainable transformation of PET waste into a kit of sensors for environmental and didactic applications

Innovative Products and Technologies

- +6 months

- Hide post

Indoor environmental quality (IEQ) system and DBT platform

Innovative Products and Technologies

- +6 months

- Hide post

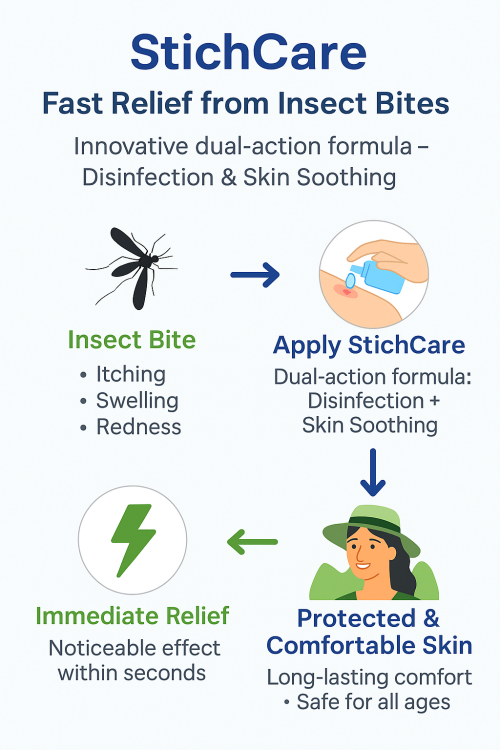

“StichCare – Instant Relief for Mosquito and Insect Bites”

Innovative Products and Technologies

- +6 months

- Hide post

Synergistic bioremediation composition for hydrocarbon pollutant degradation

Patents for licensing

- +6 months

- Hide post

Airable Research Lab, business line of Ohio Soybean Council

0 Followers

30 publications

Airable Research Lab, business line of Ohio Soybean Council posted this:

0 Followers

Bio-based Petroleum Jelly Alternative

Innovative Products and Technologies

- +6 months

- Hide post

A bio-based paste made from renewable materials for packaging applications

Innovative Products and Technologies

- +6 months

- Hide post

A carbonic anhydrase with high stability and catalytic efficiency

Innovative Products and Technologies

- +6 months

- Hide post

A complete recycle system for Lithium-ion battery materials

Innovative Products and Technologies

- +6 months

- Hide post

- 1

- 2