Showing 1 to 15 of 2076 results

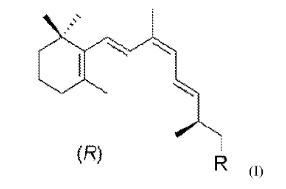

Precursor compounds for providing retinoids of the vitamin A5 pathway and uses thereof

Patents for licensing CINBIO

Point of Use Decentralized Delivery Fresh Drinking Water Daily via Atmospheric Water Generators

Innovative Products and Technologies Green Technology Global, Inc.

Paper-based temperature sensor with high sensitivity

Patents for licensing Consejo Superior de Investigaciones Científicas

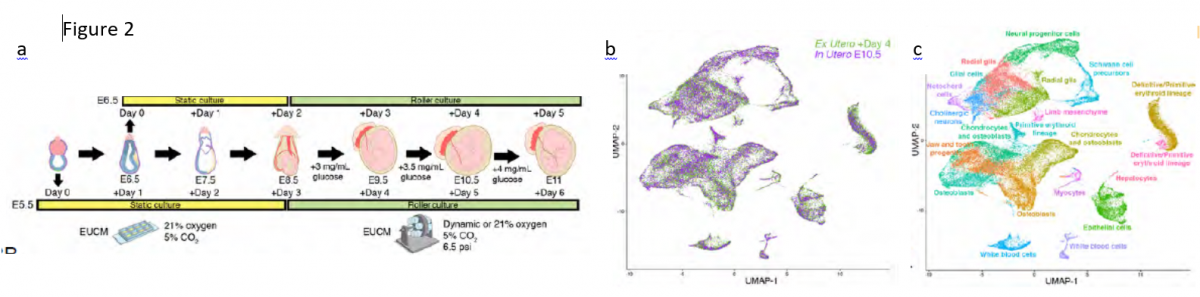

Artificial Womb Device for Extended Mammalian Embryogenesis

Patents for licensing Yeda

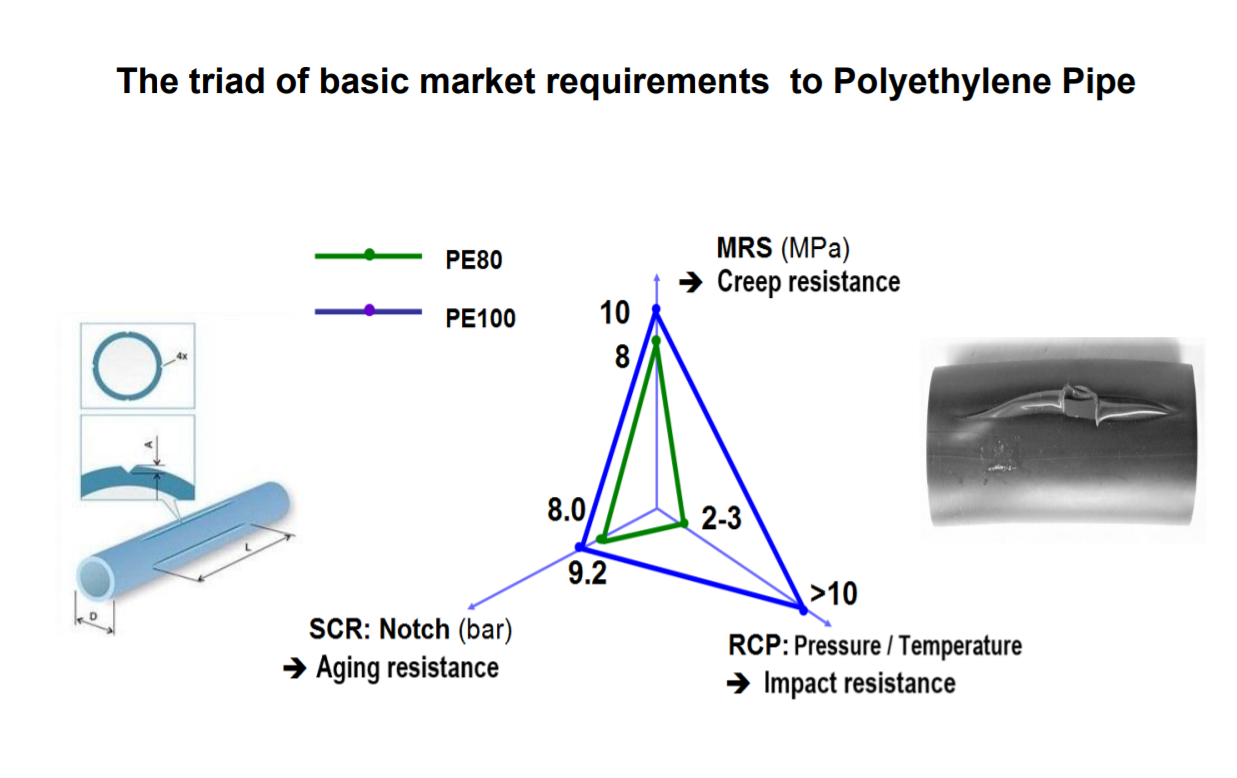

Project: Innovative pilot production modified compounds by PE125 standard for multifunctional applications.

Innovative Products and Technologies Graft Polymer UK Ltd

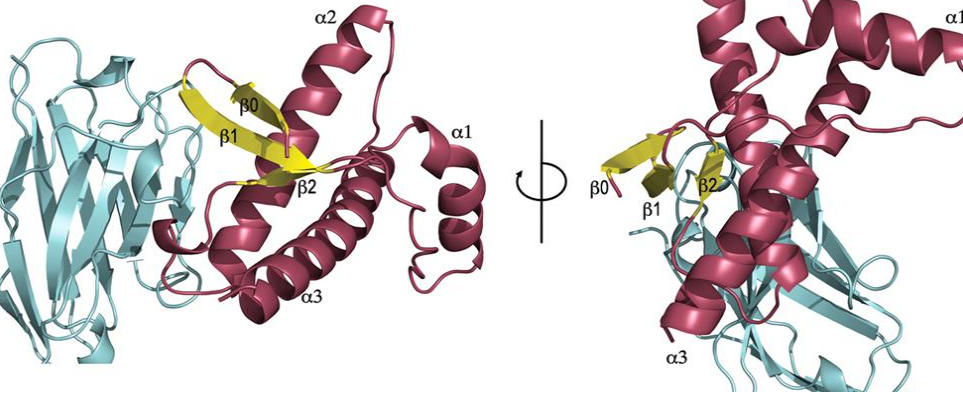

THERAPEUTIC TREATMENT AGAINST NEURODEGENERATIVE PRION DISEASES

Patents for licensing SISSA

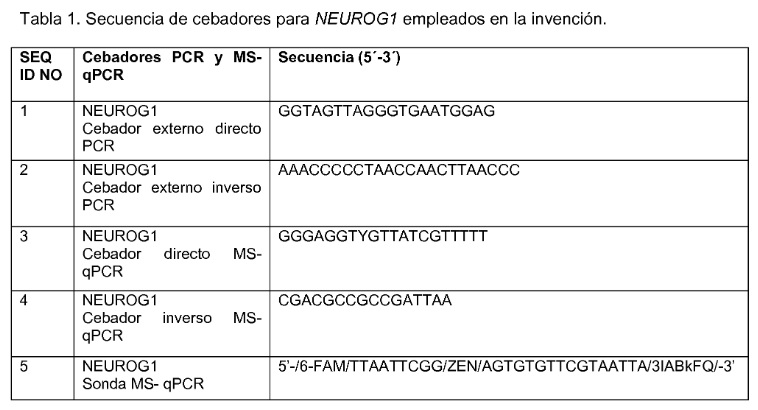

Non-invasive method for the diagnosis and screening of colorectal cancer and advanced adenomas in asymptomatic individuals

Patents for licensing CINBIO![RNA Targeted Library for post transcriptional gene regulation researches, anticancer, antiviral and antibacterial drug discovery […]](https://static1.innoget.com/uploads//a00f99d109d7028322bc0729ae707cb3e8afc5ec.jpg)

RNA Targeted Library for post transcriptional gene regulation researches, anticancer, antiviral and antibacterial drug discovery […]

Research Services and Capabilities Otava Research Institute

Method for preparing advanced Eco-friendly incombustible biocomposite

Innovative Products and Technologies Korea Institute of Energy Research

Graphene-based drug delivery device for mucosal and transmucosal administration

Patents for licensing SISSA

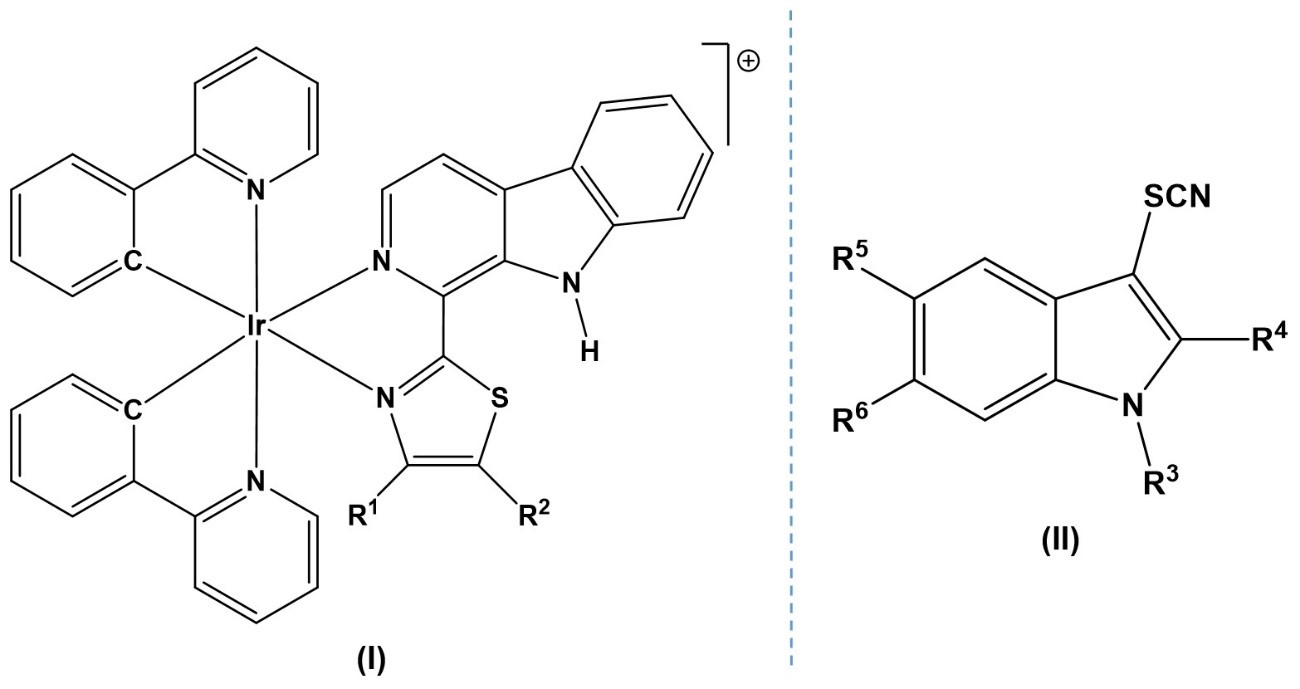

New iridium(III) complexes with application as photo-catalyst and for the treatment of cancer

Patents for licensing UNIVERSIDAD DE BURGOS

The World's 1st and Only Large Contractible Shipping Containers

Patents for licensing K-Tech R & D Corporation

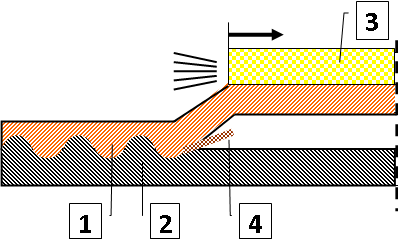

Explosive cladding for the electrical industry

Innovative Products and Technologies Laser Consult Ltd.

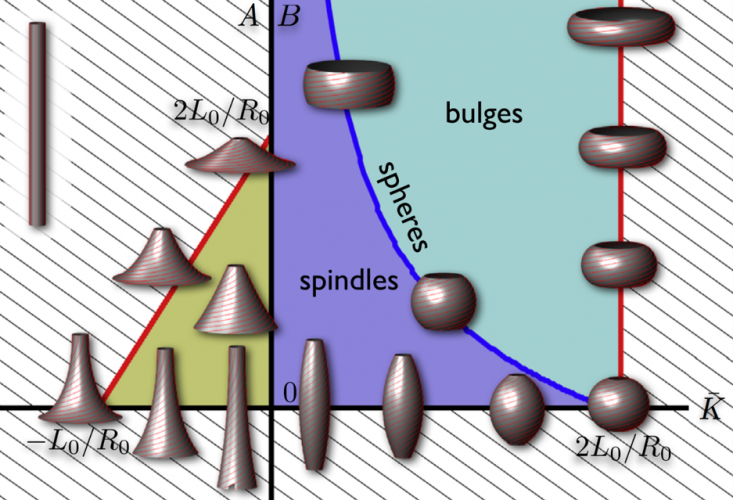

FLEXIBLE DEFORMABLE SHEET STRUCTURE

Patents for licensing SISSA![Reusable device that allows the circulation of a constant volume of electrolyte in tests on rotating bending fatigue test machines[…]](https://static8.innoget.com/uploads//a84f79ecec17c1bc422893b22993853c6c20771a.jpg)