Showing 1 to 15 of 2076 results

![A Fluidized Bed Riser Adsorption System for Selective Protein Recovery [FBRAS]](https://static3.innoget.com/uploads//f04f322327c1fb94c7c55ad506334936a79fd928.png)

A Fluidized Bed Riser Adsorption System for Selective Protein Recovery [FBRAS]

Innovative Products and Technologies Luxembourg Institute of Science and Technology (LIST)

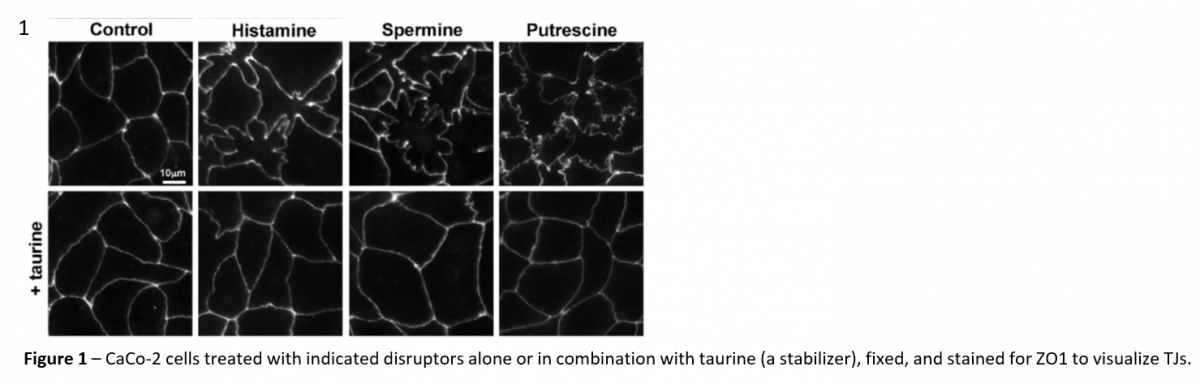

Imaging Platform for IBD Drug Discovery

Patents for licensing Yeda

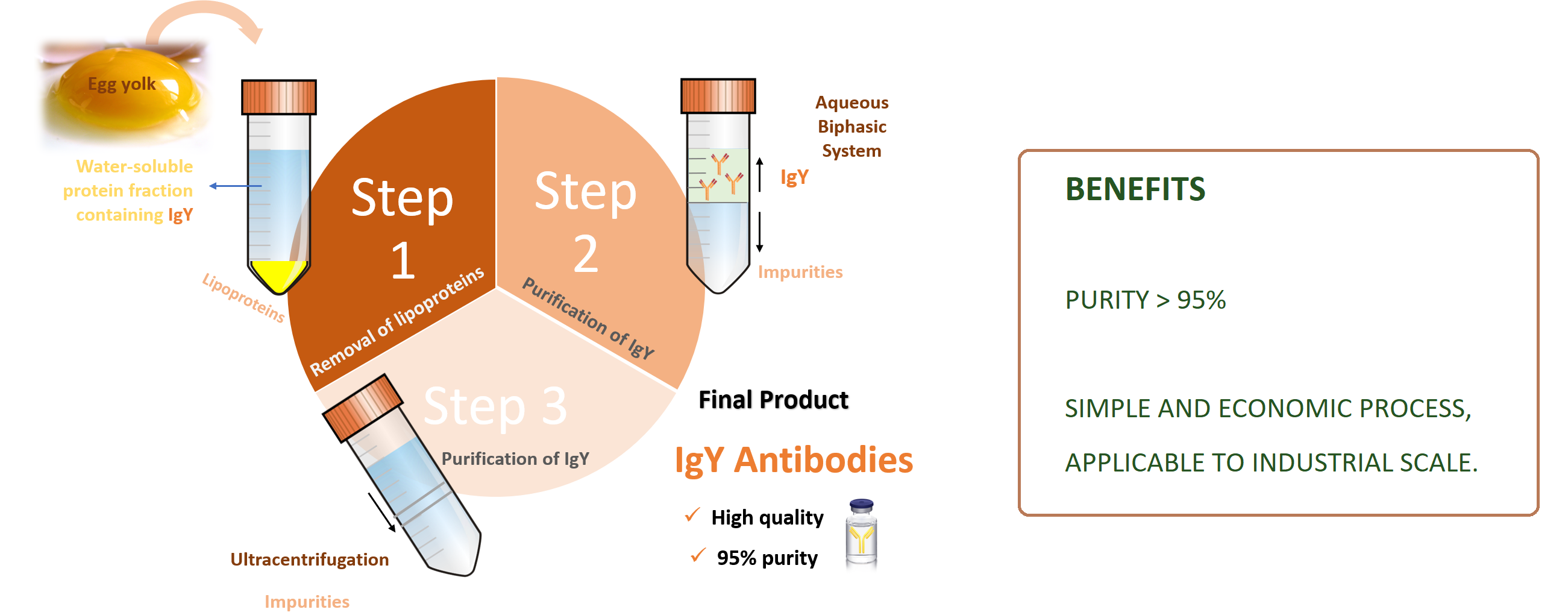

Immunoglobulin Y Purification, Its Products And Uses

Innovative Products and Technologies uacoopera

Technology for leachate treatment coming from the landfill

Innovative Products and Technologies Biogas & Gases Technologies

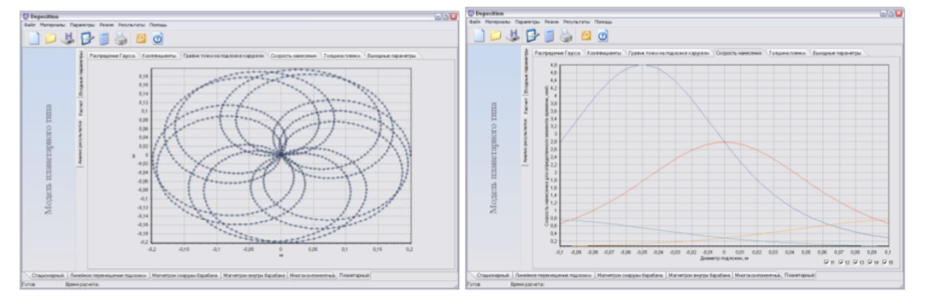

Software for simulation “DEPOSITION”

Innovative Products and Technologies BSUIR R&D Department

A novel mild and efficient method to prepare ε-Caprolactam, the precursor of Nylon 6

Patents for licensing University of Vigo

Device to determine the food shelf-life

Patents for licensing Consejo Superior de Investigaciones Científicas

The complete Eco-fertilizer based on sewage sludge and by-products

Knowhow and Research output Cracow University of Technology

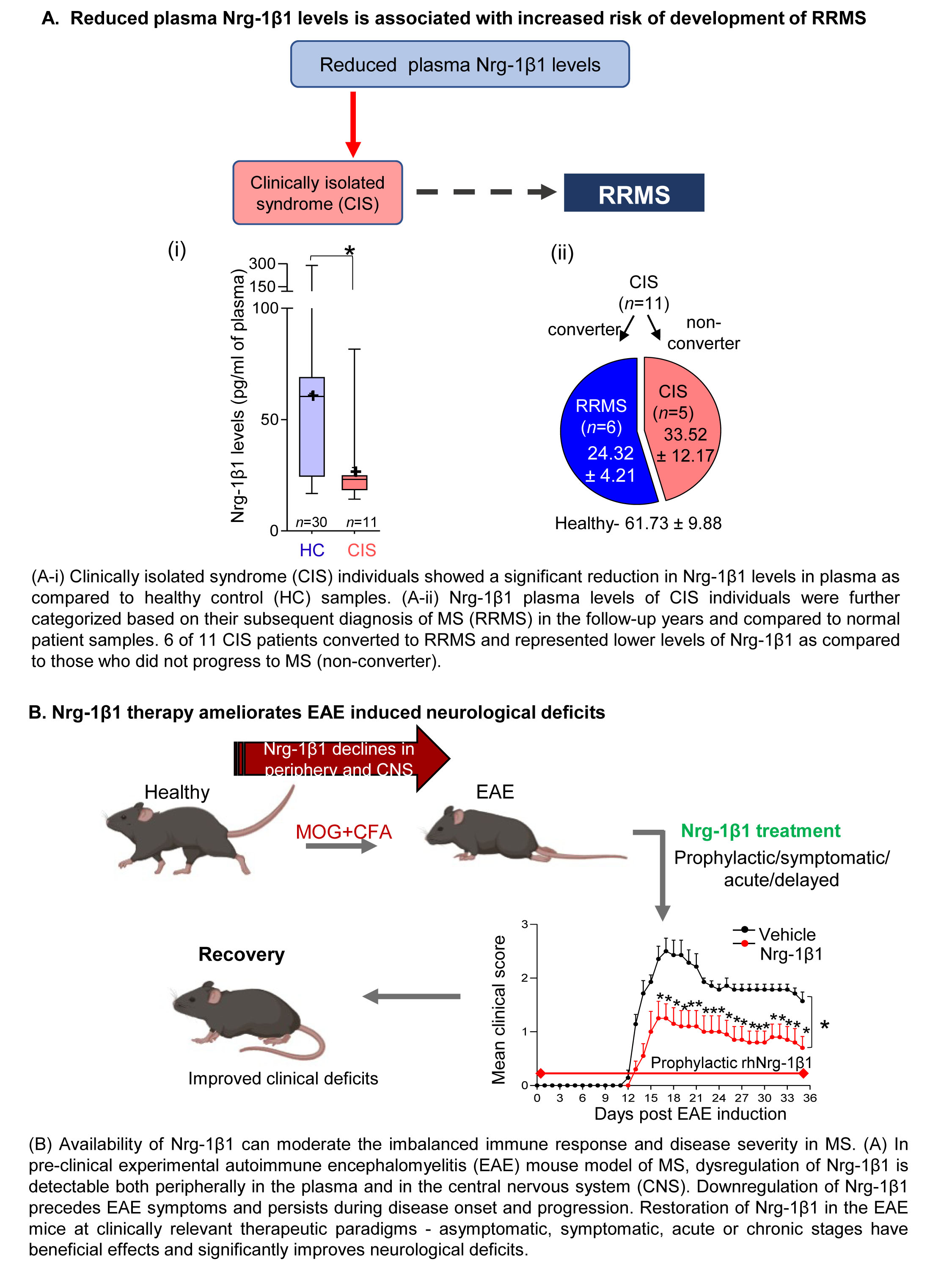

Diagnosis and Treatment of Multiple Sclerosis

Innovative Products and Technologies University of Manitoba

New orthotic glove designed to amplify hand strength

Patents for licensing Universitat Politècnica de Catalunya - UPC

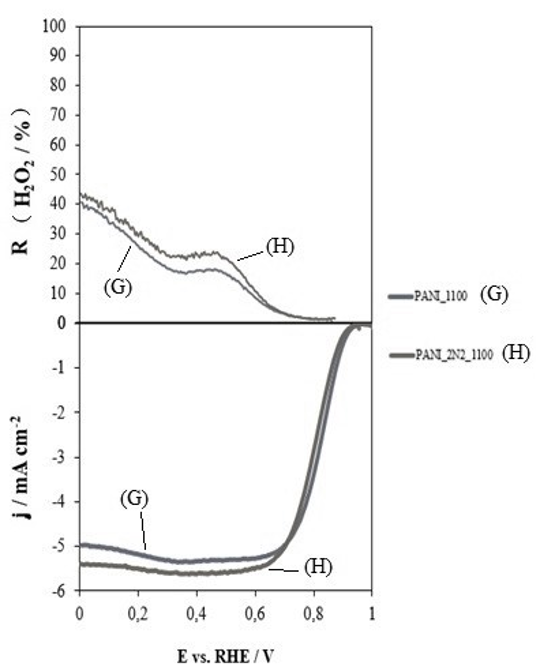

New metal-free electrocatalysts for fuel cells

Patents for licensing Universidad de Alicante

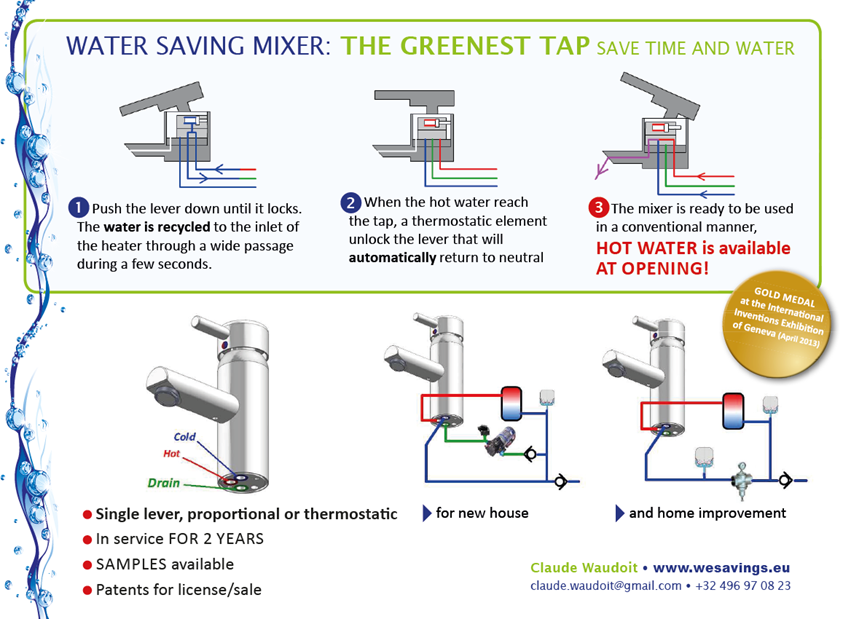

Water and Energy saving faucets

Patents for licensing Claude Waudoit

Device to reinforce the ankle and improve the footprint

Innovative Products and Technologies Universidad de Granada![New non-destructive method for “in situ” monitoring of anticorrosive protection of organic coatings Authors: Xosé Ramón Nóv[…]](https://static6.innoget.com/uploads//d93d782c4fb4b96712cf4e5f3eaf653ed109c322.png)

New non-destructive method for “in situ” monitoring of anticorrosive protection of organic coatings Authors: Xosé Ramón Nóv[…]

Patents for licensing University of Vigo