Showing 1 to 15 of 2456 results

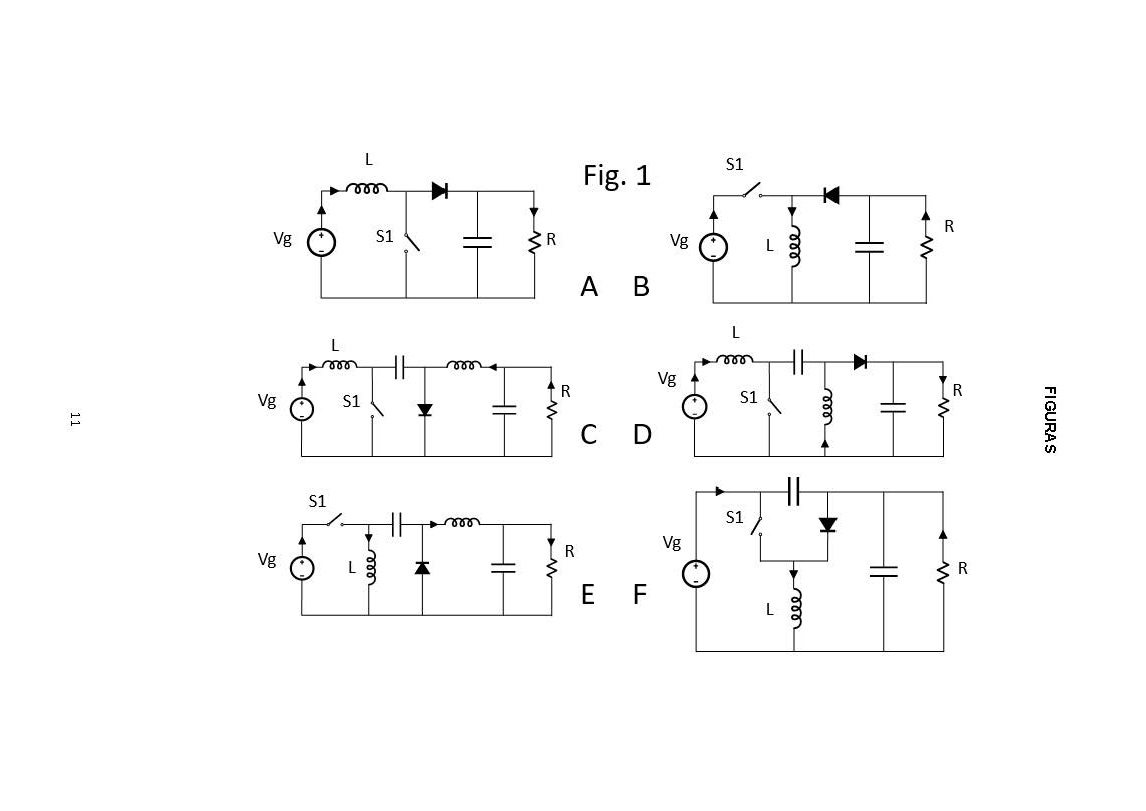

NEW CONFIGURATIONS OF CC-CC CONVERTERS OF ONE INPUT AND MULTIPLE OUTPUTS WITHOUT TRANSFORMER AND POWER CONVERTER THAT APPLY THEM

Patents for licensing University of Huelva

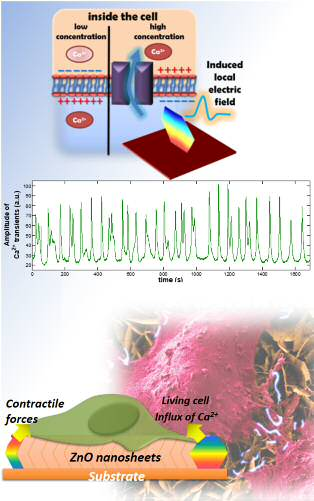

Biocompatible self-generating cell stimulator

Patents for licensing Consejo Superior de Investigaciones Científicas

Alpha Lifetech-Phage Display For Antibody Discovery

Research Services and Capabilities Alpha Lifetech Inc.

Granular Biomass: Method for Wastewater Treatment

Innovative Products and Technologies Universidad Adolfo Ibáñez

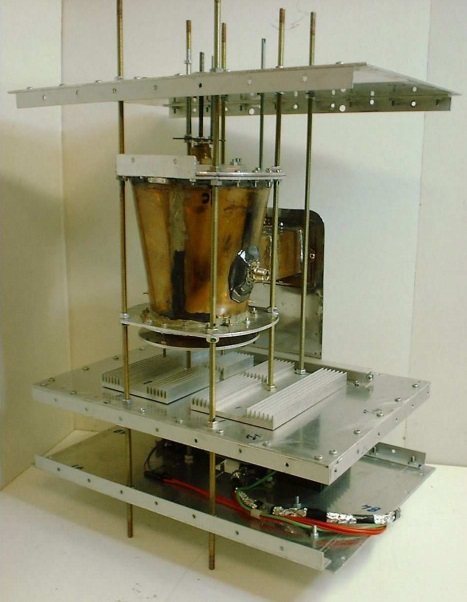

EmDrive two is new version of this machine, which provides huge thrust, big enough for satelites and flying vehicles.

Knowhow and Research output private researcher

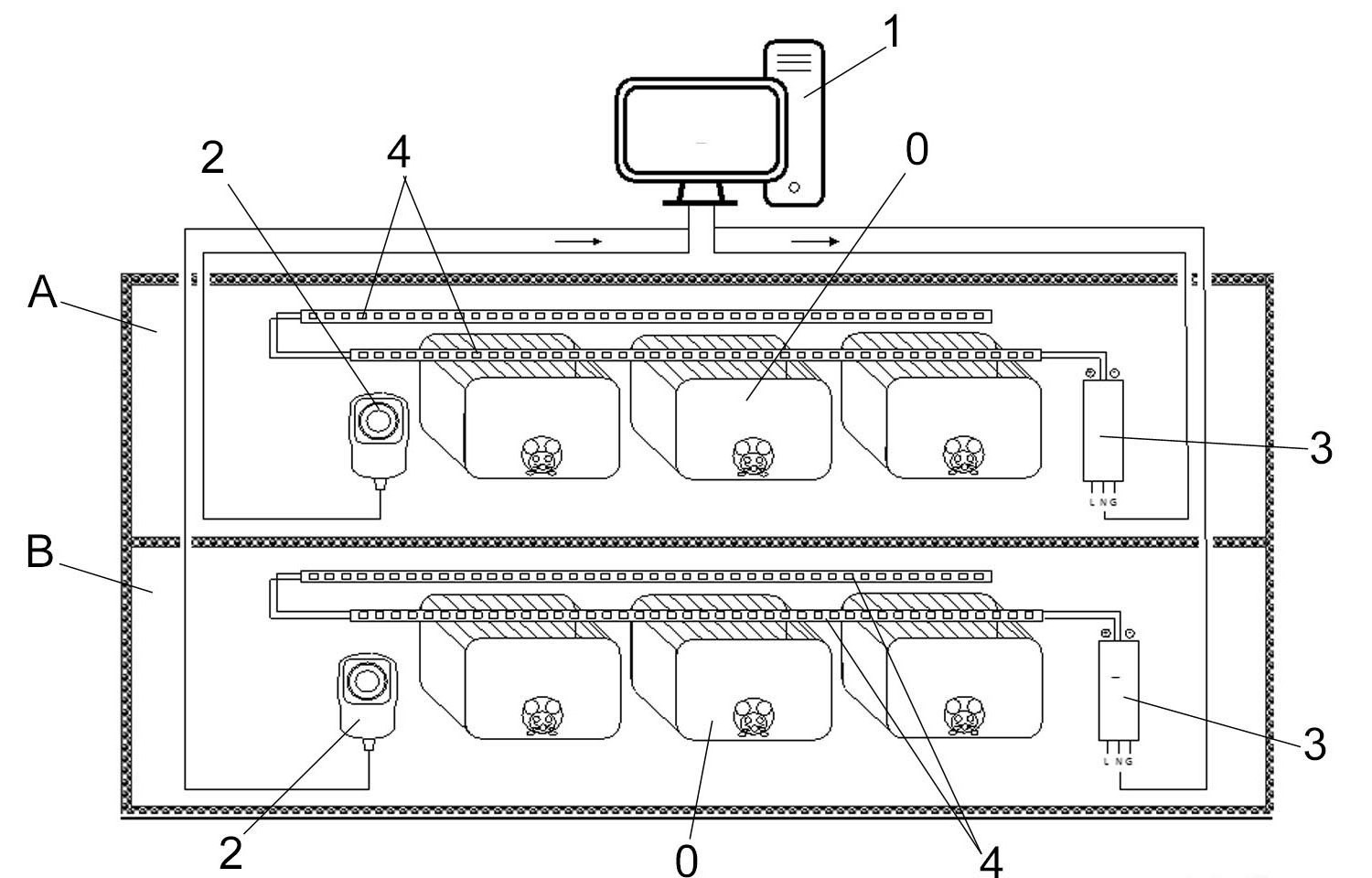

Novel individualized, homogeneous and adjustable lighting system for animals

Patents for licensing Universidad de Alicante

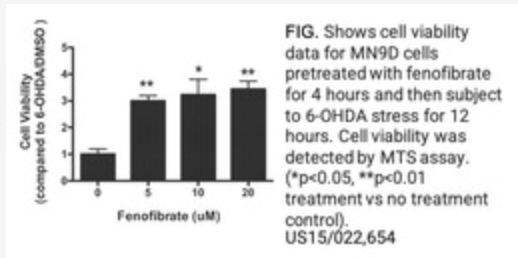

Repositioning Fenofibrate for the Treatment of Neurodegenerative Disease

Innovative Products and Technologies Georgetown University

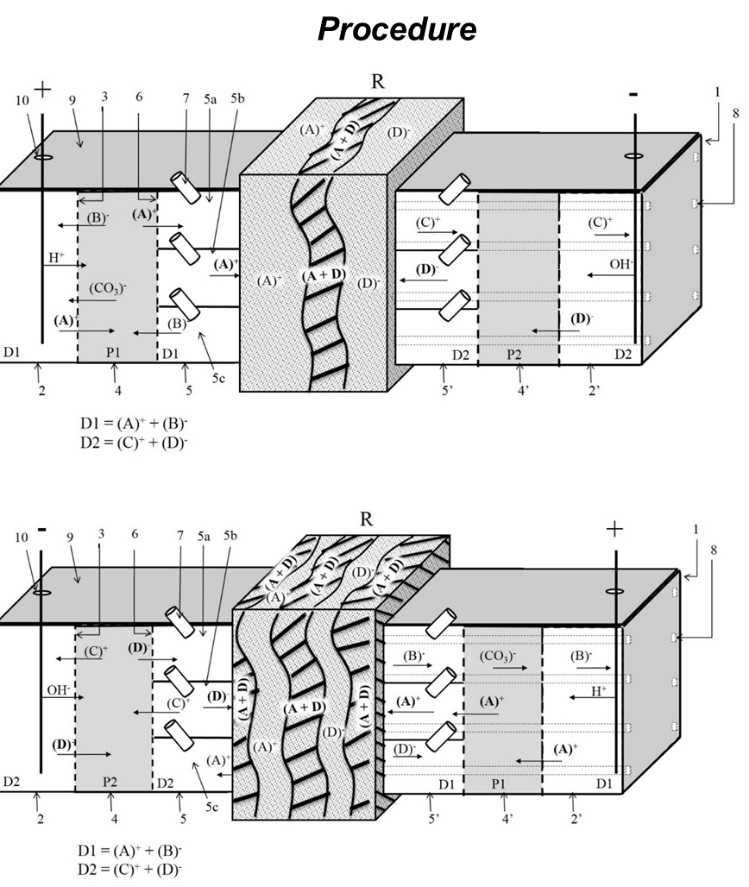

Electrokinetic device and procedure for consolidation of porous materials

Patents for licensing University of Vigo

Speech Gap Test – novel automatic speech recognition of Mild Cognitive Impairment

Patents for licensing University of Szeged![A new method of obtaining mixoxanthophylls from Arthrospira platensis dye extracts (from spirulina) for use in the pharmaceutical […]](https://static6.innoget.com/uploads/88e3c8b21489c0f2a98efd73be95b10d4e5f691f.jpg)

A new method of obtaining mixoxanthophylls from Arthrospira platensis dye extracts (from spirulina) for use in the pharmaceutical […]

Patents for licensing Jagiellonian University

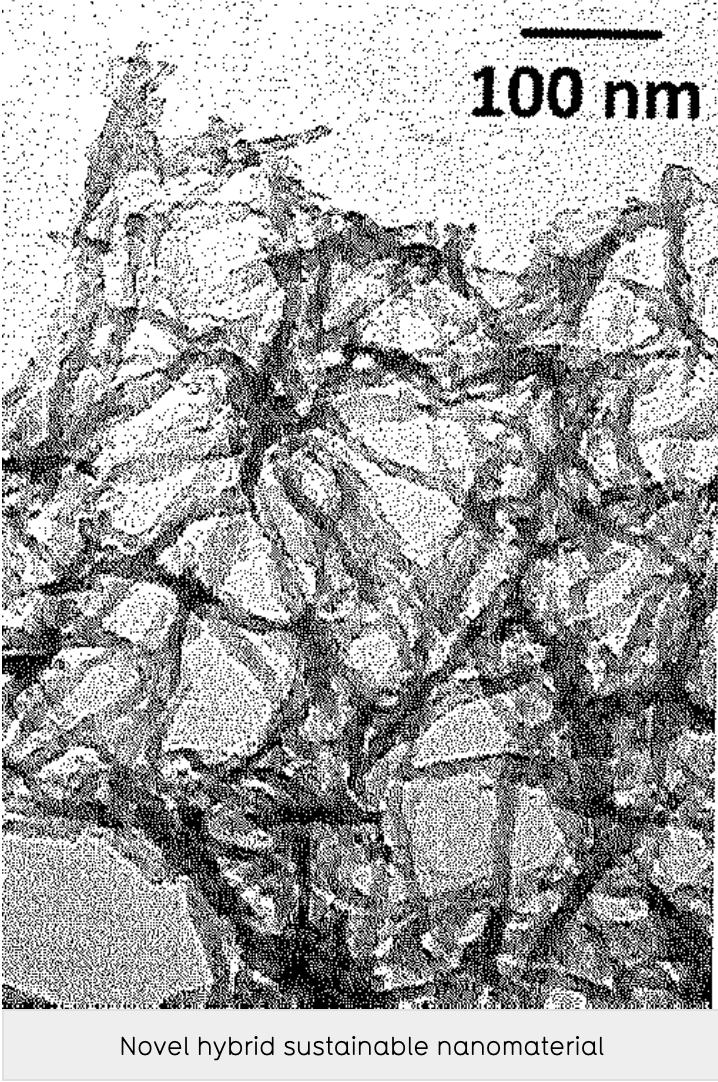

Process to prepare amine-functionalized cellulose nanocrystals for applications such as an antimicrobial agent or catalyst

Innovative Products and Technologies University of Waterloo

Augmented Reality on Android: Arquiz

Innovative Products and Technologies UNIVERSIDAD DE BURGOS

Custom FLI I Monoclonal Antibody

Innovative Products and Technologies Georgetown University

Low energy building design and thermal refurbishment of existing buildings

Research Services and Capabilities Cracow University of Technology