Showing 1 to 15 of 2456 results

Advanced organic compounds with enhanced thermal energy storage capacity

Patents for licensing Universitat de Lleida

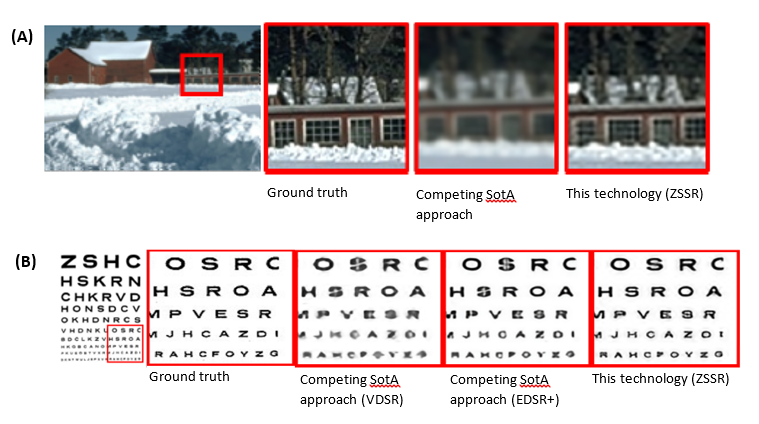

Super resolution from a single visual source

Patents for licensing Yeda

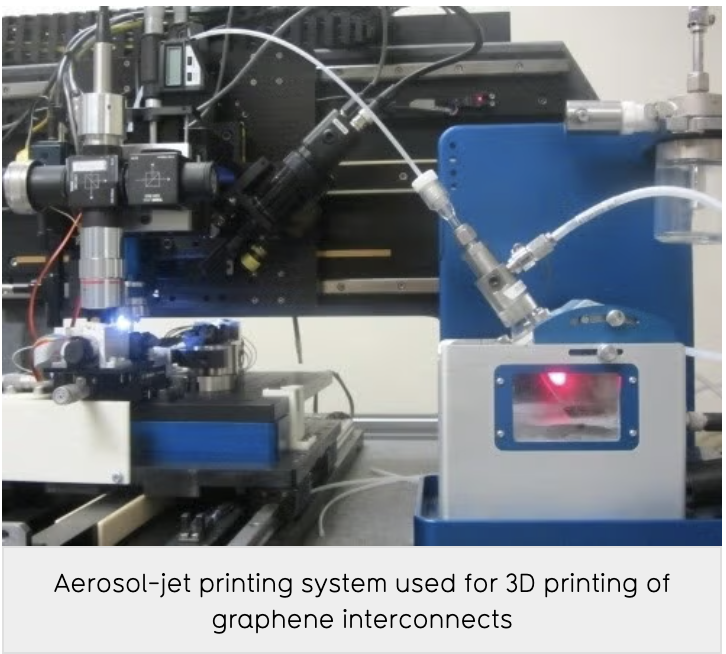

Graphene printing and additive manufacturing

Innovative Products and Technologies University of Waterloo

Rehabilit-AR: Augmented Reality for Rehabilitation

Innovative Products and Technologies UNIVERSIDAD DE BURGOS

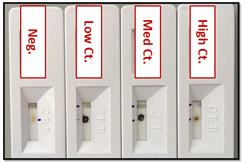

Universal sensor platform for immunoassay

Patents for licensing Universidad de Alcalá-OTRI

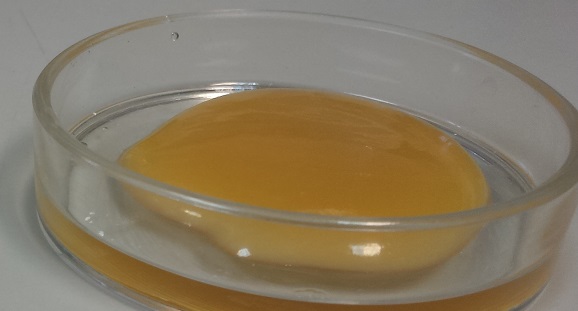

Rich Fertilize in Siderophore, that allows to cure iron chlorosis

Patents for licensing Universidad Adolfo Ibáñez

Novel Biodegradable Fluorescent Nanoparticles for Early Detection of Pancreatic Cancer

Innovative Products and Technologies Georgetown University

New holographic lenses for augmented reality applications

Patents for licensing Universidad de Alicante

Deflection Gauge

Innovative Products and Technologies CSIR

Biofouling resistant coatings

Knowhow and Research output National Biofilms Innovation Centre

SURFACE MODIFIED LITHIUM MANGANESE OXIDE FOR LITHIUM EXTRACTION

Innovative Products and Technologies University of Alberta, Technology Transfer Services

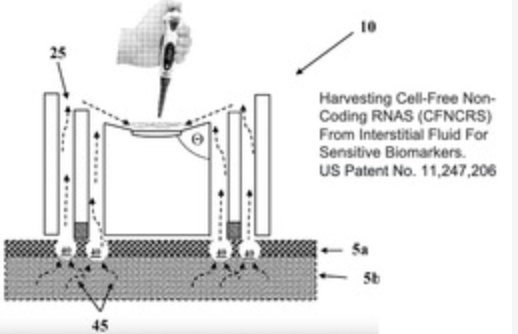

Harvesting miRNAs from Interstitial Fluid for Sensitive Biomarkers

Innovative Products and Technologies Georgetown University

Dual-Electrode in situ Infrared Spectroscopy for Fuel Cells and Batteries

Innovative Products and Technologies Georgetown University

Suppression of Impulsive Noise for 4G cell phones

Patents for licensing University of Vigo