Showing 1 to 15 of 2455 results

Tools for gender sensitisation in educational institutions

Patents for licensing Universidad de Alicante

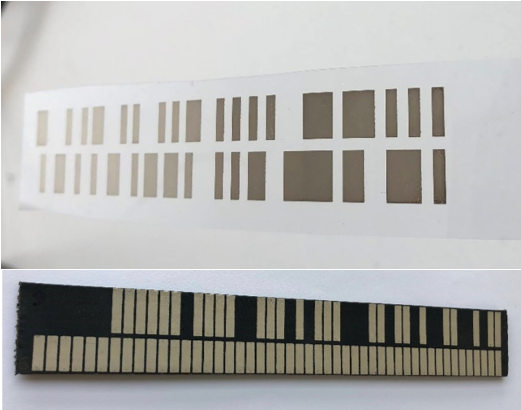

High capacity electromagnetic encoders for motion control applications and near-field Chipless-RFID system

Knowhow and Research output Universitat Autonoma de Barcelona

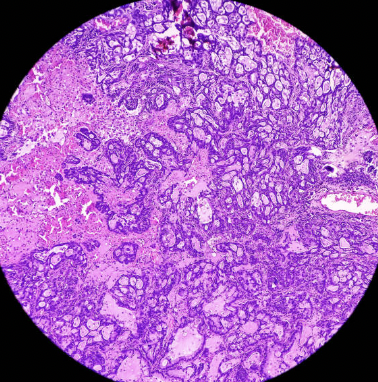

Biomarkers for the early detection of subclinical atherosclerosis

Patents for licensing Spanish National Center for Cardiovascular Research (CNIC)![A new packaging system for a real PICK AND PACK solution dedicated to warehouse logistics (e-commerce, automated picking order lin[…]](https://static3.innoget.com/uploads//a4b911ea7998fd0fa100a3cb2d882798c88f168c.jpg)

A new packaging system for a real PICK AND PACK solution dedicated to warehouse logistics (e-commerce, automated picking order lin[…]

Innovative Products and Technologies INAWA

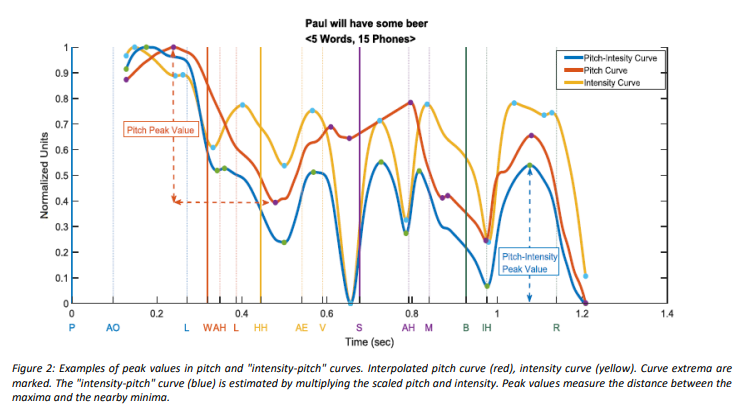

Prosody Based Speech Analysis

Patents for licensing Yeda

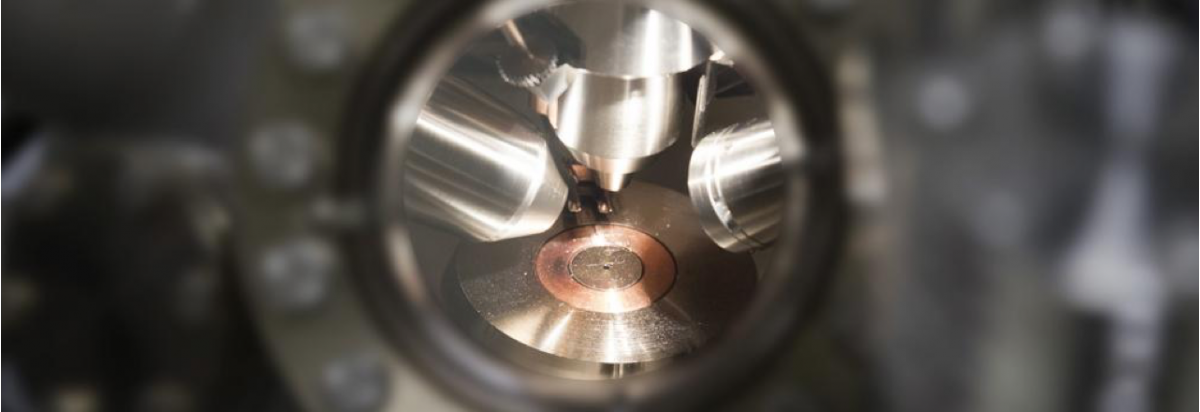

Piezomagnetic ε-Fe2O3 crystals

Patents for licensing ICMAB-CSIC

Mapping & localization without LIDAR: A robust camera SLAM solution

Innovative Products and Technologies University of Waterloo

_3D variable density printing_

Innovative Products and Technologies University of Waterloo

Stress and metabolic monitoring system to improve fish production

Patents for licensing Spanish National Research Council

FN NANO®️ technology and its contribution to ESG (Environmental, Social, Governance).

Innovative Products and Technologies FN NANO CANADA

Gas Coupling

Innovative Products and Technologies CSIR

Precursor compounds for providing retinoids of the vitamin A5 pathway and uses thereof

Patents for licensing CINBIO

New sustainable adsorbent for bleaching efficient industrial effluents

Patents for licensing University of Vigo

Catalyst for nitrous oxide (N2O) decomposition

Patents for licensing Consejo Superior de Investigaciones Científicas