Showing 1 to 15 of 2455 results

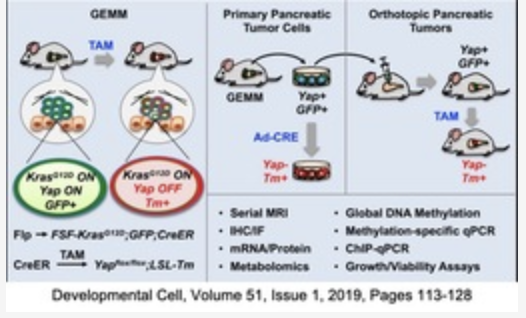

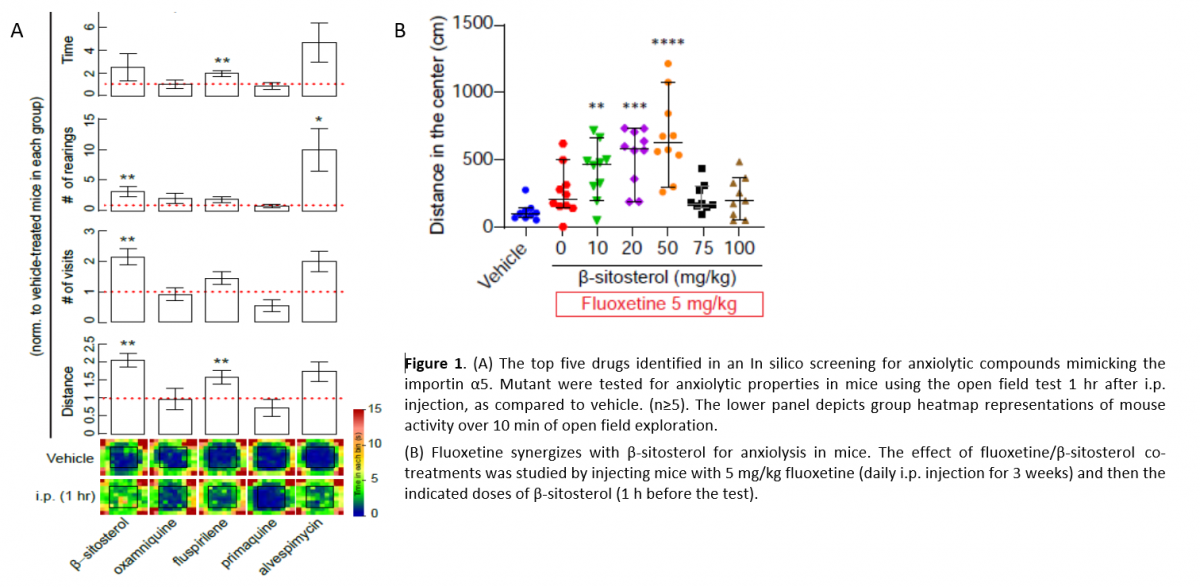

Treatment of Psychiatric Disorders by Inhibiting Importin Alpha 5

Patents for licensing Yeda

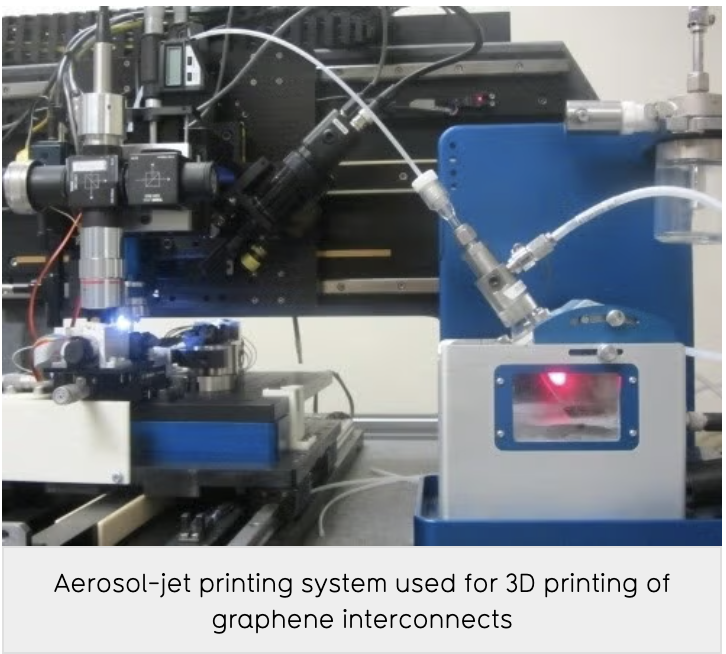

Graphene printing and additive manufacturing

Innovative Products and Technologies University of Waterloo

Healthy, Active and Satisfactory Aging Program with institutionalized seniors (HASAPIS)

Innovative Products and Technologies UNIVERSIDAD DE BURGOS

Process for cooling Photovoltaic Modules

Innovative Products and Technologies BPE e.K.

Green Cements, an innovative way to reduce clinker usage while reusing slag

Knowhow and Research output Universidad Adolfo Ibáñez

Biodegradable CCK-receptor Targeted Nanoparticle for the Treatment of Cancer

Innovative Products and Technologies Georgetown University

Mobile APP Windows Wireless Base LPG Cylinder Tracking bar code tag technology

Innovative Products and Technologies XiangKang

Umbiflow low-cost Doppler ultrasound device for better primary health care services for pregnant women

Innovative Products and Technologies CSIR

Quick RESCUE. New foldable, self-inflating, light and highly portable device for water rescue and lifesaving

Innovative Products and Technologies DIPSALUT

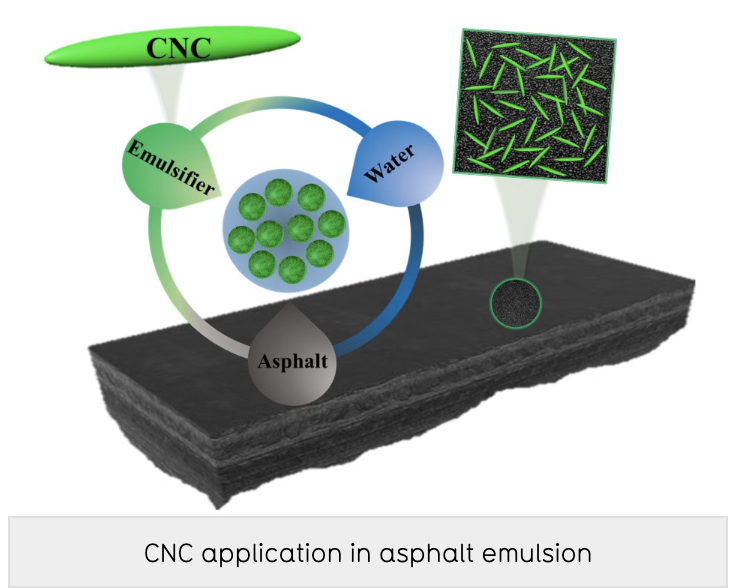

A stable, environmentally friendly emulsifier for asphalt binder

Innovative Products and Technologies University of Waterloo

Apparatus and Method for Delivery of Antimicrobial During a Transdermal Sampling and Delivery Process

Innovative Products and Technologies Georgetown University

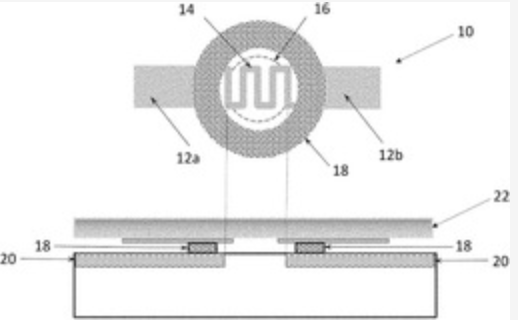

Advanced Electrochemical NMR with Interdigitated Electrodes for High-Resolution In-Situ Analysis

Innovative Products and Technologies Georgetown University

3D printer for the in-situ building of habitable modules with a raw mixture of binders and the soil of Mars

Patents for licensing UATEC - Unidade de Transferência de Tecnologia

Sustainable and cost-effective method for the isolation and concentration of viruses

Patents for licensing UNIVERSIDAD DE BURGOS