Never miss an update from Universidad de Alicante

Create your free account to connect with Universidad de Alicante and thousands of other innovative organizations and professionals worldwide

The Adhesion and Adhesives Laboratory of the University of Alicante has developed a new method (equipment and process) to determine the degree of self-repair and to monitor the kinetics of self-repair of polymeric materials. The new method also makes it possible to follow the self-repair process of composites, ceramic materials, materials based on cement, mortar or concrete, and textile materials.

TECHNICAL DESCRIPTION

This is a new method (equipment and process) that allows determining in situ the self-repair of materials, as well as quantifying the efficiency of the self-repair and monitoring the kinetics of the self-repair process.

This invention would be applicable to polymeric materials, composites, ceramic materials, materials based on cement, mortar or concrete, and textile materials.

The method consists of perforating the material by allowing a stream of inert gas to flow through the perforated hole, so that the decrease in gas flow through the perforation is directly related to the kinetics of the self-repair process. When the gas flow is interrupted, the self-healing process is complete.

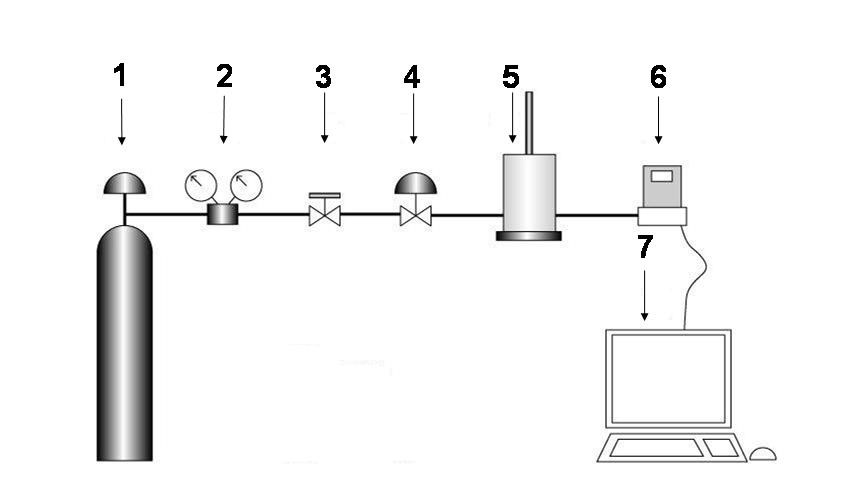

The system (see Figure 1) consists of an inert gas bullet, a pressure regulator, a gas flow shut-off and control valve, the self-repair measurement equipment, a flow meter and data acquisition equipment. In addition, the self-repair equipment contains a gas inlet and outlet and a stem with the piercing element.

Figure 1: Schematic of the material self-repair measurement equipment: 1- Gas bullet; 2- Pressure regulator; 3- Shut-off valve; 4- Gas flow control valve; 5- Main body; 6- Flow meter; 7-Data acquisition device.

As for the process followed to quantify the self-repair, this consists of placing a piece of material in the self-repair equipment, hermetically sealing it. A constant flow of inert gas is passed through for the duration of the measurement process. The sample is pierced with the shank oriented piercing tool (as many times as necessary). The stem is removed from the sample, the gas flow and the time it takes for the gas to stop passing through the sample is measured, at which point self-repair is considered to have occurred.

TECHNOLOGY ADVANTAGES AND INNOVATIVE ASPECTS

MAIN ADVANTAGES OF THE TECHNOLOGY

The main advantages of this technology are as follows:

• Simple method

• Fast method

• Efficient method

• Reproducible method

• It does not require the application of external stimuli (heat, radiation or chemical reactions).

• Several in situ measurements can be performed on the same sample.

• The sample can be of any geometry and with a very wide range of dimensions and thickness.

• The sample can be heated to temperatures above room temperature.

• The stem and piercing element allow 360° rotation.

• The gas flow output of the main body of the self-repair measuring equipment is continuously monitored by a flow sensor.

INNOVATIVE ASPECTS

This is the first method and measuring equipment that allows direct measurement of the degree of self-repair and/or monitoring of the kinetics of self-repair in materials. This invention represents a breakthrough in the development and implementation of this type of materials, with multiple applications, in society.

CURRENT STATE OF DEVELOPMENT

A prototype has now been successfully developed by the Adhesion and Adhesives Laboratory.

COLLABORATION SOUGHT

Companies interested in acquiring this technology for commercial exploitation through patent licensing agreements are sought.

Ahead of the current Coronavirus outbreak, Innoget is fully committed to contributing to mobilizing scientific and expert communities to find a real solution to the Covid-19 pandemic. Therefore, we're supporting worldwide calls and programs that could help in any aspects of the coronavirus crisis.

Is your organization promoting or looking for innovation or research initiatives to mitigate the Covid-19 outbreak? Email us at covid19@innoget.com to list them.

Channeled through Innoget's online open innovation network, initiatives in the health, virology, medicine, or novel technologies applied to human health, among others, are listed and disseminated to Innoget members -ranging from hospitals, research institutes, scientists, businesses, and public administrations- and innovation partners worldwide.

Create your free account to connect with Universidad de Alicante and thousands of other innovative organizations and professionals worldwide

Send a request for information

to Universidad de Alicante

Technology Offers on Innoget are directly posted

and managed by its members as well as evaluation of requests for information. Innoget is the trusted open innovation and science network aimed at directly connect industry needs with professionals online.

Need help requesting additional information or have questions regarding this Technology Offer?

Contact Innoget support