Never miss an update from Javier Montiel Bonmatí

Create your free account to connect with Javier Montiel Bonmatí and thousands of other innovative organizations and professionals worldwide

The "Advanced Materials" research group at the University of Alicante has developed a foamed material comprising three phases: a structural matrix, at least one host phase, and a fluid. This material is characterized by the fact that the structural matrix comprises a plurality of interconnected porous cavities, the host phase(s) is/are housed within at least one porous cavity of the structural matrix and the fluid is housed within the porous cavities. The host phase(s) is/are housed within the porous cavities of the structural matrix without maintaining any bond with the latter.

The structural matrix may consist of a material of a metallic, polymeric or ceramic nature or mixtures thereof. Meanwhile, the host phase(s) is/are a functional material, the fluid being a liquid or a gas.

These materials have many potential uses, among which one is as a catalyst material or as a support for catalysts.

Companies interested in the commercial exploitation of this material are sought through a patent license agreement.

The "Advanced Materials" research group at the University of Alicante has developed a foamed material with application in catalysis that comprises a structural matrix, at least one host phase and a fluid.

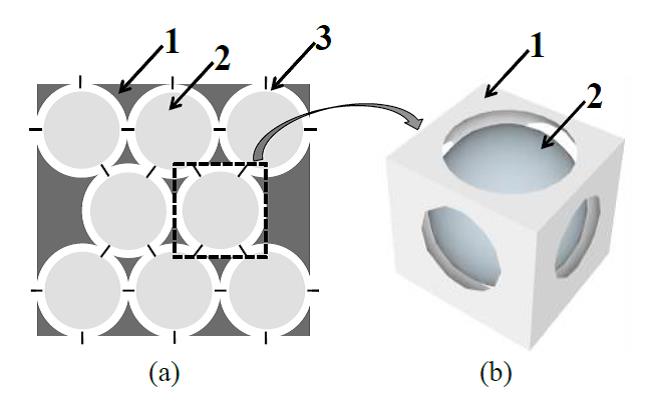

This foamed material is characterized because the structural matrix comprises a plurality of interconnected porous cavities, the host phase is housed within at least one porous cavity of the structural matrix and the fluid is housed within the porous cavity (Figure 1).

Figure 1. Schematic illustrating the interconnection of existing pores in a foamed material with structural matrix (1) and with host phase (2) and the way in which a host particle is housed in a porous cavity (3) of the foamed material. (a) two-dimensional drawing in which the lines represent interconnecting openings between pores; and (b) three-dimensional representation of a representative volume fraction containing a host particle housed in a porous cavity.

The host phase, in a finely divided form of particles or fibres, is housed within the porous cavity of the structural matrix, and maintains no bond with it, so that between the walls of the porous cavity of the foamed material and the surface of the host phase there is a space gauge that is occupied by the fluid.

The structural matrix of the foamed material may consist of a material of a metallic, ceramic or polymer nature or mixtures thereof.

The host phase of the foamed material, preferably in a finely divided state (particles or fibres), is a functional material, i.e. any material that confers a certain function, such as, for example, an adsorbent function. These include: carbon, active carbon, organo-metallic skeleton materials (MOFs), etc. The foamed material can be made up of several host phases of a different nature, so that each of them provides a different functionality to the final foamed material.

The fluid inside the porous cavity of the foamed material can be a gas or a liquid. This fluid is found surrounding the entire host phase(s) in the porous cavity in such a way that the fluid can circulate within the foamed material, as it has interconnected porosity, and renew itself if a pressure gradient is imposed at its ends.

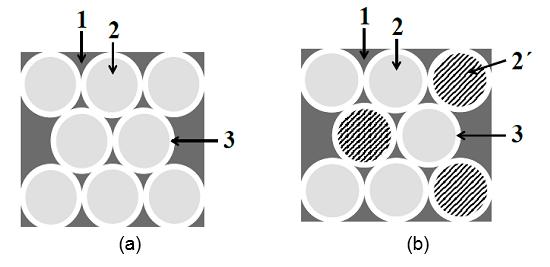

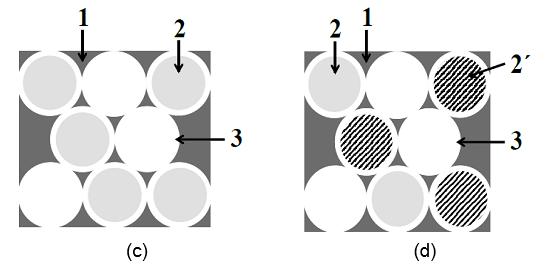

The host phase(s) of the foamed material can be housed in all or part of the porous cavities, leaving the host phase free and the rest of the cavities completely occupied by the fluid (Figure 2).

Figure 2. Different types of foamed materials with host phases that can be obtained depending on the type of porous preform from which they are departing and with host phases that do not maintain union with the structural matrix. The legend corresponds to that in Figure 1: 1 is the structural matrix, 2 is the host phase and 3 is the porous space occupied by fluid or vacuum. 2' corresponds to a host phase other than 2. The porous cavities not occupied by the host phase are free to be fully occupied by the fluid or vacuum.

MAIN ADVANTAGES OF THE TECHNOLOGY

The foamed material described has the following advantages:

The competitive advantages of this material with respect to those used in catalysis are the following:

INNOVATIVE ASPECTS

In the field of catalysis there is no material with the characteristics of the described material. The material has passed a patentability examination.

CURRENT STATE OF DEVELOPMENT

The material has been developed on a laboratory scale, although the infiltration processes are easily scalable.

MARKET APPLICATION

The present invention falls within the field of foamed materials and in particular refers to an interconnected pore foamed material containing within its porous cavities at least one host phase, which gives specific functionalities to the foamed material.

This material is particularly useful as a catalyst material or as a support material for catalysts. The material allows catalytic active materials to be housed in the host phases and ensures that the passage of fluids through it. In addition, this material can be considered multi-catalytic when different host phases are combined, which allow the different catalytic centres to be physically separated.

In addition to this use, foamed material can also be used:

COLLABORATION SOUGHT

The research group is looking for companies, especially manufacturers of catalysts, interested in acquiring this technology for commercial exploitation through:

Ahead of the current Coronavirus outbreak, Innoget is fully committed to contributing to mobilizing scientific and expert communities to find a real solution to the Covid-19 pandemic. Therefore, we're supporting worldwide calls and programs that could help in any aspects of the coronavirus crisis.

Is your organization promoting or looking for innovation or research initiatives to mitigate the Covid-19 outbreak? Email us at covid19@innoget.com to list them.

Channeled through Innoget's online open innovation network, initiatives in the health, virology, medicine, or novel technologies applied to human health, among others, are listed and disseminated to Innoget members -ranging from hospitals, research institutes, scientists, businesses, and public administrations- and innovation partners worldwide.

Create your free account to connect with Javier Montiel Bonmatí and thousands of other innovative organizations and professionals worldwide

Send a request for information

to Javier

Technology Offers on Innoget are directly posted

and managed by its members as well as evaluation of requests for information. Innoget is the trusted open innovation and science network aimed at directly connect industry needs with professionals online.

Need help requesting additional information or have questions regarding this Technology Offer?

Contact Innoget support