- Anonymous Organization

- From LATAM

- Responsive

- Project Size Range : 250,000 - 1,000,000 €

- Posted by

Desired outcome

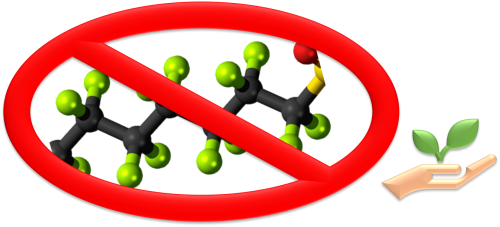

We are seeking a solution that eliminates oxides formation from AHSS and promotes surface corrosion inhibition. The solution should be able to be incorporated into a standard electro-deposition coating process (e-coat). Some AHSS are prone to exhibit high surface corrosion with evidence that some of them may present a thicker oxide formation at welded areas. This condition may, therefore affect the adhesion of the anti-corrosion coating system, ultimately causing painted components to be more prone to corrosion.

We are seeking innovative technologies capable of efficiently and completely remove oxides in AHSS surface and welded areas while promoting surface corrosion inhibition.

Details of the Innovation Need

Background

We produce a variety of structural steel assemblies by encompassing manufacturing processes in forming, gas metal arc welding (GMAW) and painting. The last of these processes involves protecting the assemblies against corrosion through a system involving cleaning, rinsing, phosphatizing and an E-coat deposition. The whole painting process is done by fully immersing the assemblies in tanks for the pre-treatment and E-coat deposition stages at specified cycles times to then be allowed to cure in an oven.

Cleaning AHSS becomes critical due to these assemblies’ characteristics:

- Assemblies have an important percentage of heat-affected zones (HAZ) due to the GMAW process, in which oxide formation might be thicker than regular oxides.

- Due to the assemblies’ configuration, there is a large percentage of closed-section areas. The sought technology needs to be able to clean inside / outside of the assembly.

- Over 70 assemblies per hour are coated.

- New trends require structures to assemble AHSS with regular carbon-steel, coated steels, and aluminum. The solution needs to be compatible with a multi-material system.

We are interested in technologies that can demonstrate their solution’s cleaning effectiveness through a scalable process and partners capable to prove their solid technology, expertise, and know-how on this challenge.

We will consider for advancement an approach that meets performance criteria with acceptable economics and pathway to commercialization. While commercially available technologies are of primary interest, we will also consider maturing technologies with a reasonably short timeline to commercial viability.

Desired Solution:

The successful technology will:

•Allow a 70 assembly-per-minute submersion process;

• Will be compatible with carbon steels, coated, galvanized, galvannealed steels and aluminum;

• Have no negative impact on the steel substrate;

• Be easily implementable into existing e-coat painting lines

• Be robust and repeatable

The Solution Must Include:

Your response should address the following:

- Non-confidential description of the proposed technology and working principle

- Availability of technical data including:

- Processing rate

- Immersion times to achieve the desired cleaning

- Safety considerations for operations

- The technical maturity of the approach (concept, reduced to practice, prototype, ready to commercialize, ready to implement, commercialized)

- Pathway to commercial scale including timing, estimated budget, and capacity for manufacture

- The estimated unit cost of technology

- Position on intellectual property including patent references

- Desired relationship with us

- Team description and related experience (please update your professional and organization profile on the submission form)

The Solution should Include cost estimates and the estimated unit cost of technology.

Discarded Solutions:

The following approaches are not of interest:

- Technologies that damage the steel assembly and/or the galvanized, galvannealed coating;

- Technologies not capable of meeting throughput requirements;

- Technologies that require a change or a significant addition in the painting process.

Related Keywords

About Us

Global company manufacturer of steel assemblies. Footprint in over 10 countries. Highly focused on integration of external innovations to accelerate competitiveness.

About Innovation Needs

Innovation Needs on Innoget are directly posted and managed by its members as well as evaluation of proposals. Innoget is the trusted open innovation and science network aimed at directly connect industry needs with professionals online.