- Anonymous Organization

- From European Union

- Responsive

- Project Size Range : Strategic project backed by large scale funding €

- Posted by

Desired outcome

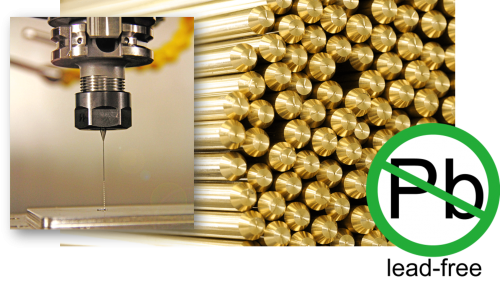

A prominent consumer goods company specializing in stationery products in the EU seeks an alternative process or tooling to facilitate the machining (e.g., microdrilling, microturning) of lead-free brass cylinders of small size factor. The existing leaded material offers high machinability and enables high production rates, qualities we aim to maintain while reducing lead content. The solution must ensure prolonged tool durability, easy chip evacuation, and excellent surface finishing of the manufactured parts, while also aligning with the chip recycling process.

The company aims to source global solutions, emphasizing experimental proof of concept beyond TRL 3, regardless of geographic origin, while ensuring marketability in both the EU and US markets, supported by relevant non-confidential data showcasing efficiency and feasibility.

Business objectives to be achieved:

In our technology roadmap, we aim to gradually substitute leaded brass with alternative solutions that eliminate the need for this element. Anticipated future regulations in the EU and US may mandate a substantial reduction in the permissible lead content in consumer products. The company's objective is to maintain current production throughput levels, minimize cost impact, and preserve existing production and machine layouts utilized in our manufacturing plants.

Tested/ Discarded solutions:

Other experimental brass alloys with low lead content have been tested over the years with unsatisfactory results, namely, excessive tool wear, insufficient chip fragmentation, difficult to recycle chips, and poor production yields.

Must haves :

Technical requirements :

- Machinability of lead-free brass cylindrical parts

- Applicable on brass alloys with lead content <500ppm

- Long tool durability

- Easy chip evacuation

- Good surface finishing of the parts

- Material recyclability

- Machining processes should include at least one of the following: Microdrilling (hole diameters of 0.5-1.5mm) Microturning

Business requirements:

- High production rates

- Low impact on machine configurations

- Low impact on manufacturing flow

Legal / Environmental requirements:

Nice to haves:

- Applicable on brass alloys with lead content <100ppm

- Cost-effective solution (process & tooling)

- Sustainable process (not aggressive chemistry, reduced waste generation, low environmental impact )

Opportunity :Preferred partnership options include R&D contracts, joint development ventures, supply agreements, and patent sales. Upon validating and demonstrating the feasibility of the proposed solution, the parties may establish a contractual agreement to transfer technology usage rights to the company.

Business timelines:

2024 Q3 Testing at R&D level.

2025 Q1 Technical feasibility assessment

2025 Q4 Testing on industrial scale

Related Keywords

About Us

We stand as a global frontrunner in fast-moving consumer goods, boasting significant innovation across various product categories. Our robust manufacturing and commercial footprint spans the globe, encompassing retail, B2B, D2C, and beyond, alongside an extensive portfolio of products. With a formidable innovation roadmap, we aim to bolster further through strategic collaborations, fostering human-centric and eco-friendly innovative solutions and products.

About Innovation Needs

Innovation Needs on Innoget are directly posted and managed by its members as well as evaluation of proposals. Innoget is the trusted open innovation and science network aimed at directly connect industry needs with professionals online.