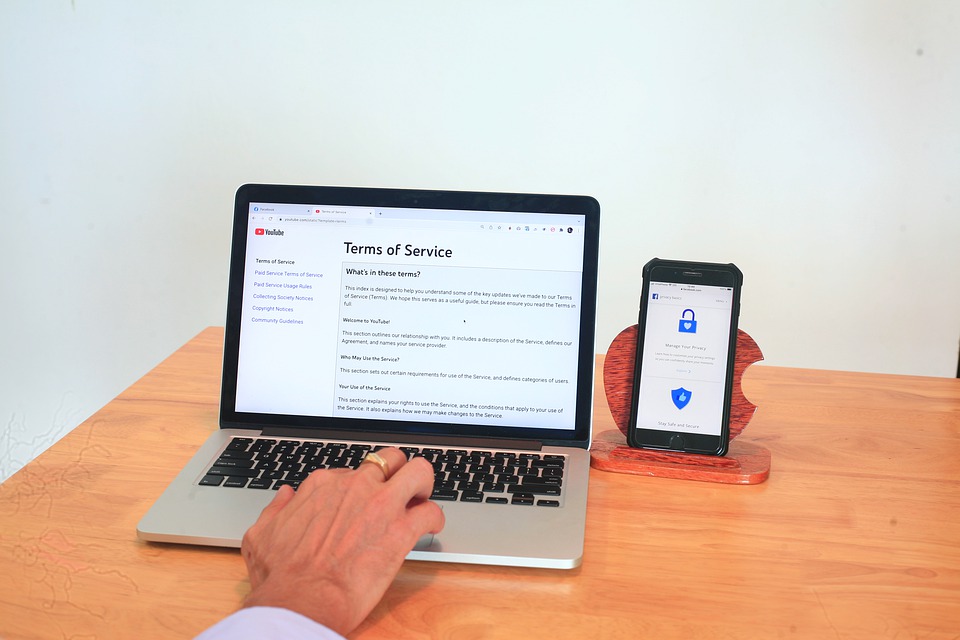

Showing 1 to 15 of 2075 results

Novel actuation system for an active orthosis

Patents for licensing Universitat Politècnica de Catalunya - UPC

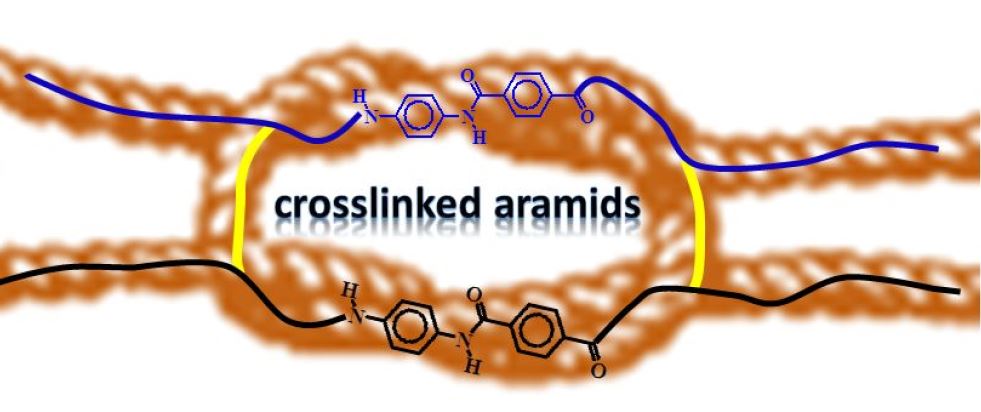

Crosslinking aromatic polyamides (aramids)

Patents for licensing UNIVERSIDAD DE BURGOS

Bracelet for postural control

Patents for licensing UNIVERSIDAD DE BURGOS

A Pack of a Routing, Fault Tolerance and Sizing Method for Dynamic WDM Optical Networks

Innovative Products and Technologies Hub APTA

New FFTH-PON Network for extended numbers of users

Patents for licensing Universitat Politècnica de Catalunya - UPC

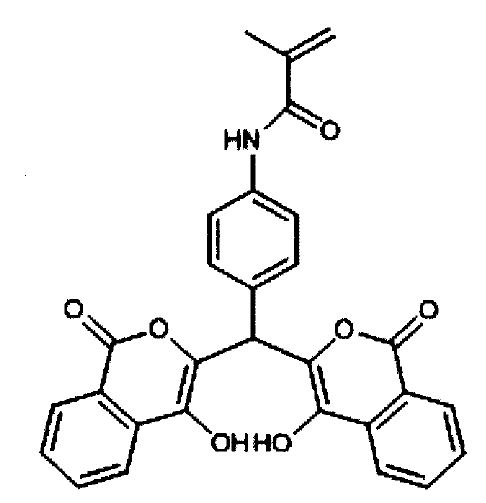

New array of sensors for the selective detection of nitro-explosive vapours (TNT, RDX, PETN).

Patents for licensing UNIVERSIDAD DE BURGOS

Quick RESCUE. New foldable, self-inflating, light and highly portable device for water rescue and lifesaving

Innovative Products and Technologies DIPSALUT

New Antiviral Drugs from Bacterial Natural Products

Patents for licensing Yeda

New device for bidirectional optical link

Patents for licensing Universitat Politècnica de Catalunya - UPC

Increasing the information capacity of optical communications through embedded data modulation over pilot symbols

Patents for licensing Instituto de Telecomunicações

A novel behavioral bioassay for preclinical testing and characterization of CNS agents

Innovative Products and Technologies RAMOT at Tel Aviv University Ltd.

Method for optimizing the transmitter power allocation in a communications system

Patents for licensing Universitat Politècnica de Catalunya - UPC

Antibody Drug Conjugates (ADCs)

Innovative Products and Technologies ALL Chemistry Inc.

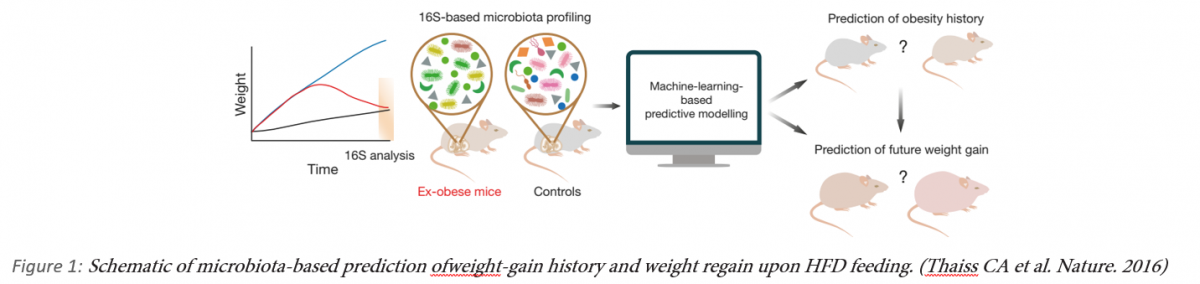

Microbiome-Based Prediction, Diagnosis, and Treatment of Relapsing Obesity

Patents for licensing Yeda