Never miss an update from Javier Montiel Bonmatí

Create your free account to connect with Javier Montiel Bonmatí and thousands of other innovative organizations and professionals worldwide

The “Ecosystem and Biodiversity Management” (Spanish initials: GEB) and “Agricultural Chemistry” (Spanish initials: QA) research groups at the University of Alicante have developed a new anoxic marine sediment remediation system and procedure that allows in situ transformation of soft, black, muddy sediment with a high organic matter content and a characteristic fetid odour into well-oxygenated, firmer sediment that has a much lower organic matter content and is no longer black or foul smelling.

The procedure involves injecting oxygen-saturated sea water into the sediment to displace anoxic pore water. A suction pump system collects sea water, which is then stored and treated in a tank by means of a bubbling system to achieve oxygen saturation before being injected via nozzles into the sediment to treat, using an injection sequence of between 90-180 minutes of rest and 50-70 minutes of injection.

This technology, which has been developed at laboratory scale and is protected by patent application, could be used for remediation of anoxic sediments on shallow beaches and materials extracted during port dredging that require elimination of anoxic conditions.

The research groups are seeking companies or public sector authorities interested in commercial exploitation of the invention.

The “Ecosystem and Biodiversity Management” (Spanish initials: GEB) and “Agricultural Chemistry” (Spanish initials: QA) research groups at the University of Alicante have developed a new anoxic marine sediment remediation procedure which consists of injecting oxygen-saturated sea water into the sediment in order to displace the anoxic/hypoxic pore water it contains.

As a general rule, the concentration of dissolved oxygen in aquatic hypoxic/anoxic sediments is very low or null. Application of this procedure improves the content of dissolved oxygen in water, facilitating oxidation of organic matter and other reduced inorganic compounds that accumulate in the sediment, and thus enhancing the environmental conditions and potential for use of these sediments. In addition, oxidation helps eliminate substances toxic to the fauna that inhabit the sediment, such as H2S, as well as foul-smelling volatile substances such as reduced sulphur compounds, which restrict the use of shallow beaches for recreational purposes.

As a result of this remediation procedure, soft, black, muddy, anaerobic sediment with a high organic matter content and a characteristic fetid odour is transformed into well-oxygenated, firmer sediment that has a much lower organic matter content and is no longer black or foul smelling.

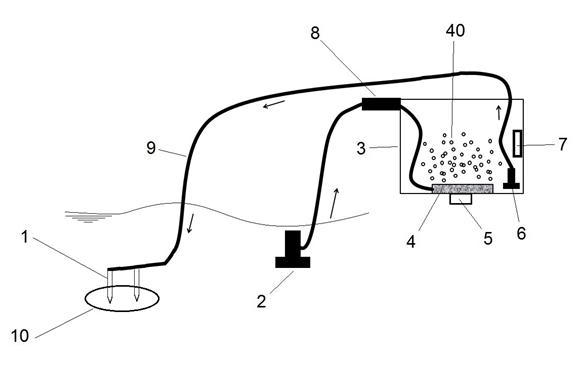

The procedure entails the following sequence of steps (Figure 1):

1. Sea water collection using a suction pump;

2. Storage of collected sea water in a tank;

3. Treatment in the tank of the collected sea water using a bubbling system to achieve a concentration of dissolved oxygen of between 6 and 9 mg O2/L at 20ºC;

4. Pump-driven injection of oxygen-saturated sea water into a hydraulic circuit equipped with multiple nozzles inserted at different depths into the sediment to treat;

5. Injection of oxygen-saturated sea water into the sediment using an injection sequence of between 90-180 minutes of rest and 50-70 minutes of injection.

Figure 1. Diagram of the injection system, showing all the elements involved in the anoxic marine sediment remediation procedure. 1) Nozzles; 2) Suction pump; 3) Tank; 4) Diffusers; 5) Air blower; 6) Drive pump; 7) Oximeter; 8) Filters; 9) Pipelines; 10) Sediment to treat; 40) Small bubbles.

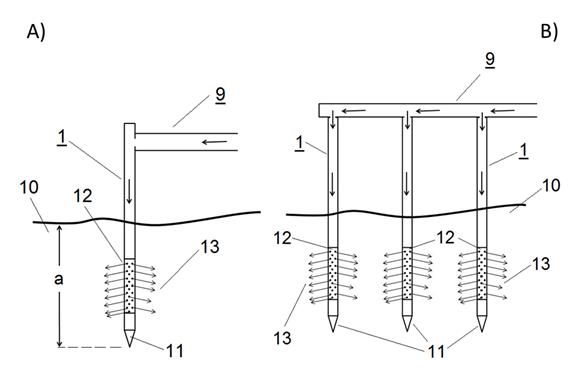

The injection nozzles form a key element of the system, and their number will depend on the number, diameter and length of the pipelines that constitute the hydraulic circuit used to inject the oxygen-saturated water into the sediment. They are opaque and rigid (made of stainless steel or PVC) and are inserted into the sediment at depths of between 10 and 30 cm (see Figure 2). Their pointed ends facilitate insertion in the sediment, and behind these they have radial perforations through which the oxygen-saturated water is pumped, creating an oxygenation bulb.

Once the injection nozzles have been inserted into the sediment to treat, oxygen-saturated sea water from the tank is injected into it. As a general rule, the pressure and flow rate used must be sufficient to displace the pore water; thus, the higher the concentration of fine sediment, the greater the pressure required. In order to achieve sediment regeneration, oxygen-saturated sea water must be injected at a frequency or cycle consisting of between 50 to 70 minutes of injection and 90 to 180 minutes of rest, for a variable length of time depending on the volume of sediment to treat but which may last up to 30 working days.

Figure 2. A) Diagram of an injection nozzle, which forms part of the system and is inserted into the marine sediment to treat; B) Diagram of a set of injection nozzles. 1) Injection nozzle; 9) Pipelines; 10) Sediment to treat; 11) Lower end of the injection nozzle; 12) Perforations; 13) Bulb; a) Depth at which the injection nozzle is inserted into the sediment.

This procedure also offers the possibility of implementing an environmental monitoring plan and testing the efficiency of the method used by analysing changes in the pore water and the treated sediment.

The great advantage of this remediation system with respect to other available decontamination techniques is its lower environmental impact, since it does not involve the introduction of exogenous substances into the environment. Instead, it simply replaces oxygen-poor water (concentrations <2 mg O2/L at 20ºC) in the sediment with oxygen-saturated sea water (concentrations ≈9 mg O2/L at 20ºC). In under twenty days, good oxygenation conditions are generated that facilitate degradation of the organic and inorganic compounds that accumulate in anoxic/hypoxic conditions and lead to the formation of unhealthy sludge.

Application of this procedure achieves in situ transformation of soft, black, muddy, anaerobic sediment with a high organic matter content and a fetid odour into well-oxygenated, firmer sediment that has a much lower organic matter content and is no longer black or foul smelling.

This greatly improves the environmental and health-related aspects of anoxic/hypoxic sediments on tourist and recreational beaches. Furthermore, remediation of sediments extracted during port dredging would allow these to be deposited onto beaches without negatively affecting the ecosystem, since the procedure eliminates the organic matter and toxic substances responsible for the black colour and foul odour.

In addition, it enhances the sediment’s capacity to host infauna of ecological, fishing or even fishkeeping interest by improving the highly anoxic conditions of the pore water and sediment.

This remediation system could also be used to immobilise certain heavy metals and other toxic inorganic compounds that accumulate in anoxic/hypoxic sediment and pore water. As a result, the sediment would no longer act as a sink for heavy metals present in the water.

This sediment remediation technique could also be used to prevent the need for dredging, which is more expensive and may even be impossible in certain locations for legal or technical reasons.

Last but not least, it could also be used as preventive measure to forestall the formation of anoxic sediments in a variety of environments (e.g. the open sea, reservoir and river beds, seagrass meadows and aquariums).

The technology described here presents the following innovative aspects with respect to other technologies available on the market:

• The type of contaminant to degrade: organic matter and inorganic substances generated in anoxic conditions;

• The zones where these occur: shallow beaches and calm waters where anoxic sediments accumulate;

• The procedure and equipment required for remediation of muddy sediments: injecting oxygen-saturated sea water is a completely novel technique.

This invention falls within the field ofdecontamination technologies for sediments affected by organic and inorganic substances, and more specifically of actions and techniques aimed atregenerating sediments, enhancing conditions for public and recreational use of beaches andenvironmental remediation of anoxic sediments extracted during port dredging.

This technology has been developed at laboratory scale.

Ahead of the current Coronavirus outbreak, Innoget is fully committed to contributing to mobilizing scientific and expert communities to find a real solution to the Covid-19 pandemic. Therefore, we're supporting worldwide calls and programs that could help in any aspects of the coronavirus crisis.

Is your organization promoting or looking for innovation or research initiatives to mitigate the Covid-19 outbreak? Email us at covid19@innoget.com to list them.

Channeled through Innoget's online open innovation network, initiatives in the health, virology, medicine, or novel technologies applied to human health, among others, are listed and disseminated to Innoget members -ranging from hospitals, research institutes, scientists, businesses, and public administrations- and innovation partners worldwide.

Create your free account to connect with Javier Montiel Bonmatí and thousands of other innovative organizations and professionals worldwide

Send a request for information

to Javier

Technology Offers on Innoget are directly posted

and managed by its members as well as evaluation of requests for information. Innoget is the trusted open innovation and science network aimed at directly connect industry needs with professionals online.

Need help requesting additional information or have questions regarding this Technology Offer?

Contact Innoget support