Showing 1 to 15 of 2075 results

Multilingual Translator

Patents for licensing Universitat Politècnica de Catalunya - UPC

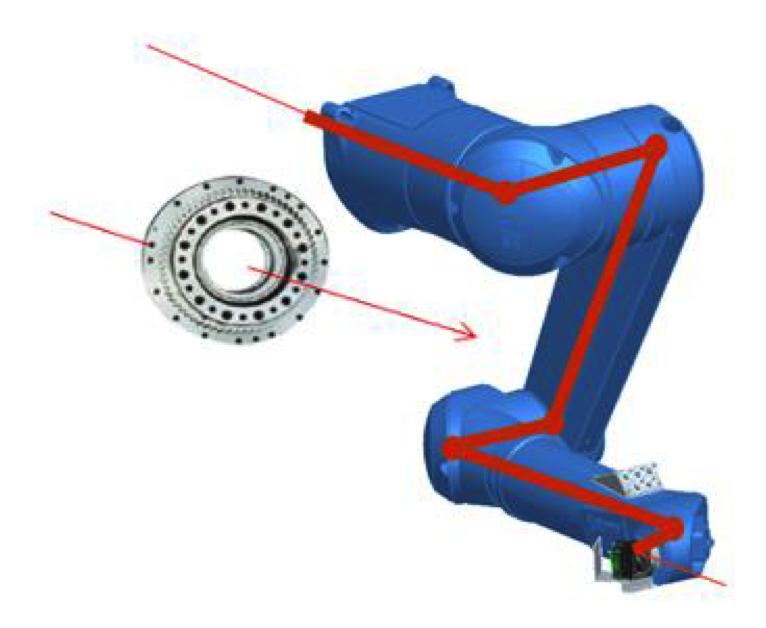

High precision High speed Robotic Laser cutting for Metals and Plastics

Innovative Products and Technologies Jenoptik Automotive North America

Method for predicting sex in fish

Patents for licensing CSIC - Consejo Superior de Investigaciones Científicas

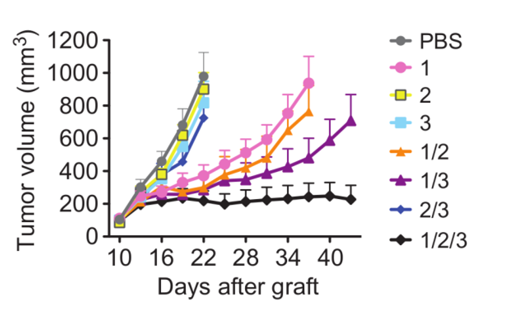

Treating Drug-Resistant Lung Cancer Using a Combination of Antibodies

Patents for licensing Yeda

High Oleic Soybean Oil Hand Sanitizer

Knowhow and Research output Airable Research Lab, business line of Ohio Soybean Council

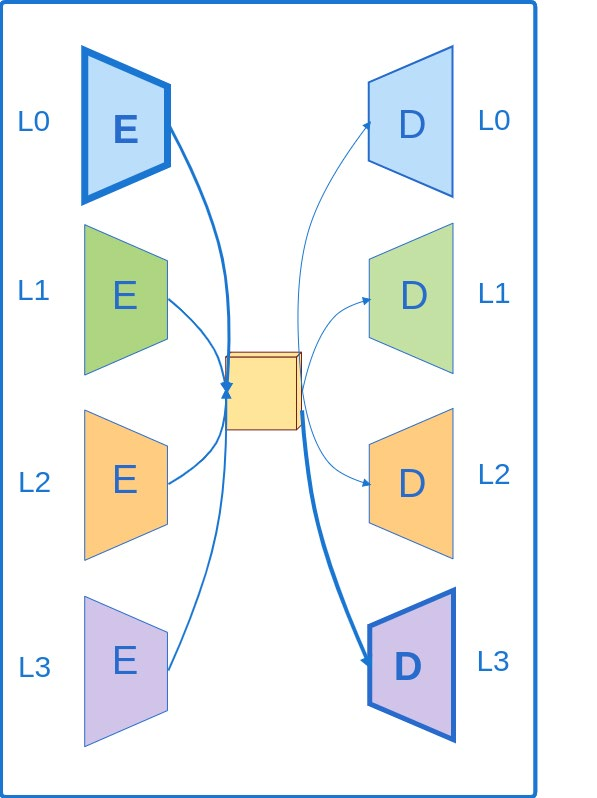

System for improving accessibility in learning platforms by using push buttons, for people with motor disabilities.

Patents for licensing Universidad de Alcalá-OTRI

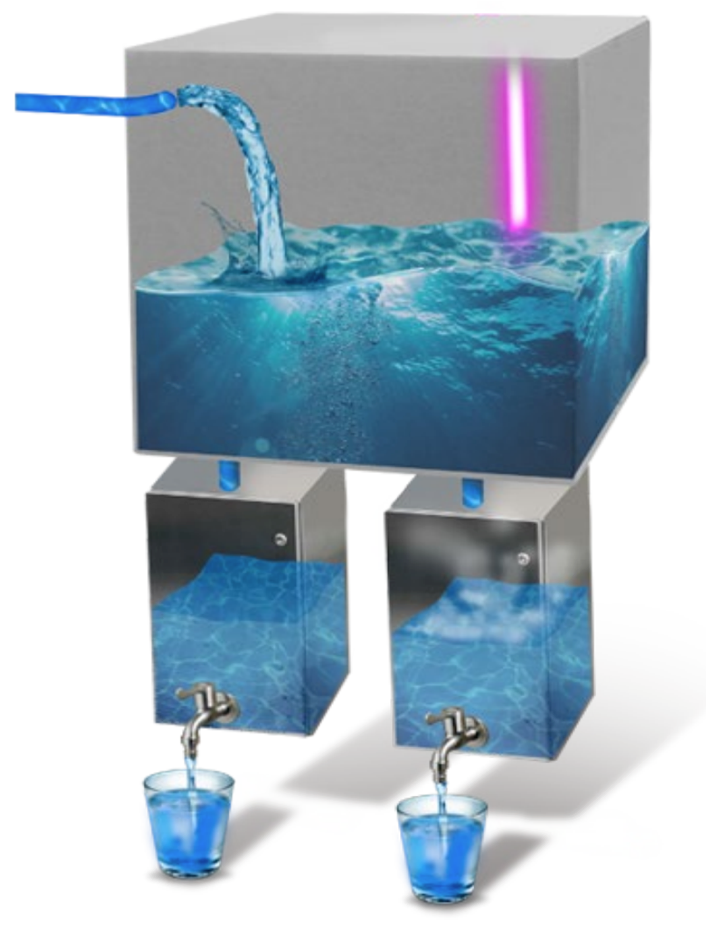

Point of Use Decentralized Delivery Fresh Drinking Water Daily via Atmospheric Water Generators

Innovative Products and Technologies Green Technology Global, Inc.

A new super-effective active substance against serious and incurable diseases.

Innovative Products and Technologies JSC Margali

Sustainable and cost-effective method for the isolation and concentration of viruses

Patents for licensing UNIVERSIDAD DE BURGOS

System for reliable detection of occupancy of parking spaces

Patents for licensing Universidad de Alcalá-OTRI

Novel self-expanding polyurethane foams intended for inert filling of pleural and other human cavities.

Patents for licensing UNIVERSIDAD DE ALICANTE

Preparation of MiRNAs libraries through nanotechnology, for massive sequencing

Patents for licensing Universidad de Granada

Ultrafast quantum random number generator Authors: Marcos Curty, Valerio Pruneri, Morgan Mitchell and Marc Jofre

Patents for licensing University of Vigo

Education system for 3D drawing chemical structures

Innovative Products and Technologies Centre Technology Transfer CITTRU