Showing 1 to 15 of 2075 results

Method and system for correcting errors in satellite positioning systems and computer program products thereof

Patents for licensing Universitat Politècnica de Catalunya - UPC![Aqueous antioxidant extracts of vegetable raw materials, procedure of obtaining and their use in the composition of a cosmetic and[…]](https://static1.innoget.com/uploads//5d466f2980870fb3f64b423920f8784068142a2c.jpg)

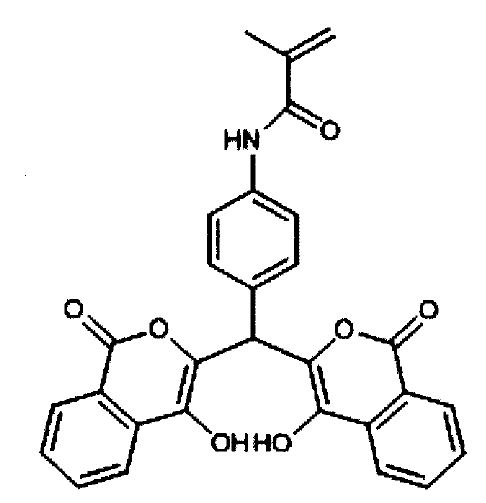

Aqueous antioxidant extracts of vegetable raw materials, procedure of obtaining and their use in the composition of a cosmetic and[…]

Patents for licensing CINBIO

Novel Combination Therapy For Improved Management of Depression

Patents for licensing Yeda

New array of sensors for the selective detection of nitro-explosive vapours (TNT, RDX, PETN).

Patents for licensing UNIVERSIDAD DE BURGOS

Knowledge on occupational safety and health (OSH)

Knowhow and Research output PEROSH

ULISENS Legionella Desktop Analyzer

Innovative Products and Technologies Biótica, Bioquímica Analítica,S.L.

Method for the optimization of large structural elements.

Research Services and Capabilities UNIVERSIDAD DE BURGOS

Piezomagnetic ε-Fe2O3 crystals

Patents for licensing ICMAB-CSIC

Odor Detection Platform - Low power, Low cost, Programmable Sensor Array

Innovative Products and Technologies University of Manitoba

An improved fast and high throughput method for the sequential measurement of nitrate and nitrite in water samples

Patents for licensing Universidad de Cádiz

Microencapsulation of enzymes to accelerate the cheese ripening process

Research Services and Capabilities UNIVERSIDAD DE BURGOS

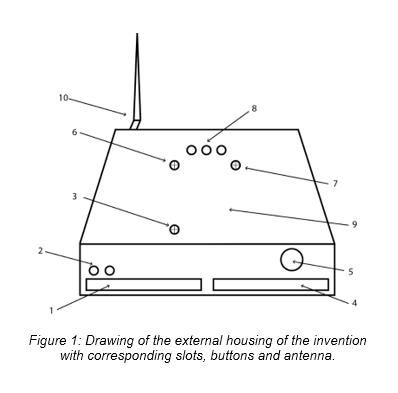

Seismic-noise recording system with real-time data visualisation

Patents for licensing Universidad de Alicante

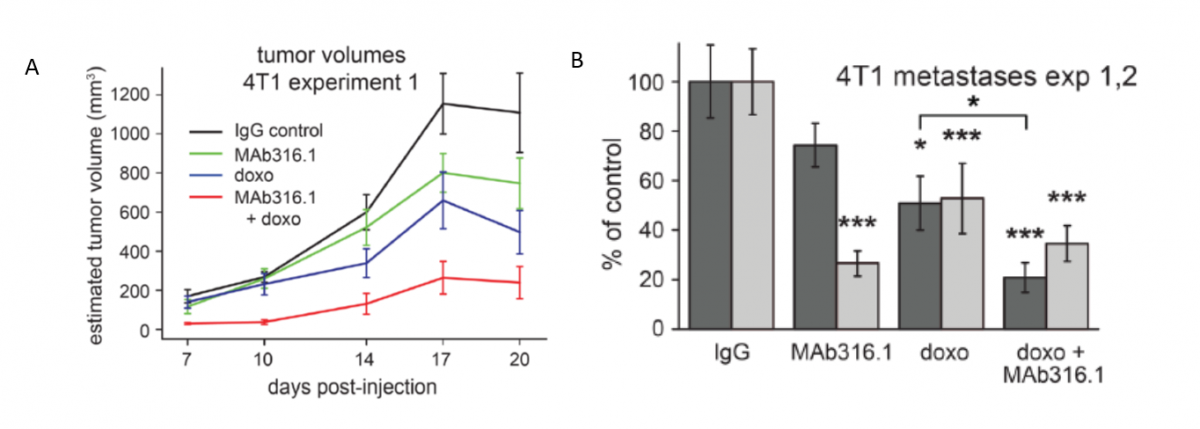

Anti-QSOX1 Antibody for Treating Cancer and Metastasis

Patents for licensing Yeda![Technology for analyzing and predicting the level of electromagnetic environmental pollution by 2G/3G/4G/5G mobile communication s[…]](https://static4.innoget.com/uploads//27bd9cb4022b5ed87d4381ce6f1dfd314f338c95.png)

Technology for analyzing and predicting the level of electromagnetic environmental pollution by 2G/3G/4G/5G mobile communication s[…]

Innovative Products and Technologies BSUIR R&D Department