Showing 1 to 15 of 372 results

Seeking Rapid Substance Detection in Inspection and Supply Chain

Specific Technical Innovation The Procter & Gamble Company

Seeking Glue-free and Plastic-free closure of paper packaging

Specific Technical Innovation Fater SpA

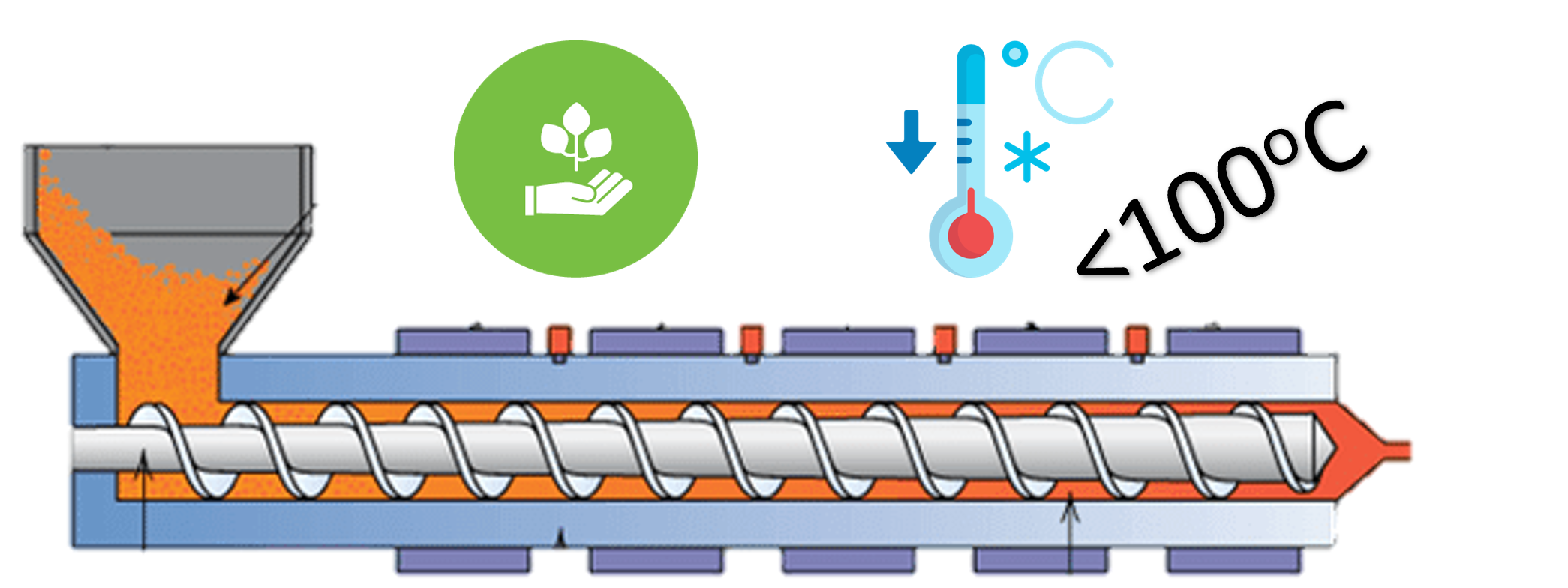

Seeking Sustainable Bio-Based Material for Low-Temperature Extrusion in FMCGs/CPGs

Specific Technical Innovation Organization from European Union

Seeking Diversifying Business Models for Aniline and Derivatives

Specific Technical Innovation inocrowd![Seeking Revolutionizing Process Efficiency and Effectiveness through Digital Technologies in Technologies in Chemical Production P[…]](https://static3.innoget.com/uploads//3382d57665093802723a79f0d5d53a0276dc8f04.jpg)

Seeking Revolutionizing Process Efficiency and Effectiveness through Digital Technologies in Technologies in Chemical Production P[…]

Specific Technical Innovation inocrowd![Seeking Sustainable packaging: Development of barrier properties to oil and grease in molded fiber (cellulose) articles (MFA) for […]](https://static5.innoget.com/uploads//4f43b4f7ede6d0b7a75de93d2d3380d7572f311e.jpg)

Seeking Sustainable packaging: Development of barrier properties to oil and grease in molded fiber (cellulose) articles (MFA) for […]

Specific Technical Innovation inocrowd

Seeking: How can we reduce costs and increase efficiency when obtaining renewable hydrogen

Specific Technical Innovation Repsol

Seeking technologies to reduce GHGs in all aspects of the supply chain and manufacturing process.

Specific Technical Innovation PepsiCo

Seeking Adhesion improvement of silicone-based coatings to metal substrate

Specific Technical Innovation Organization from European Union

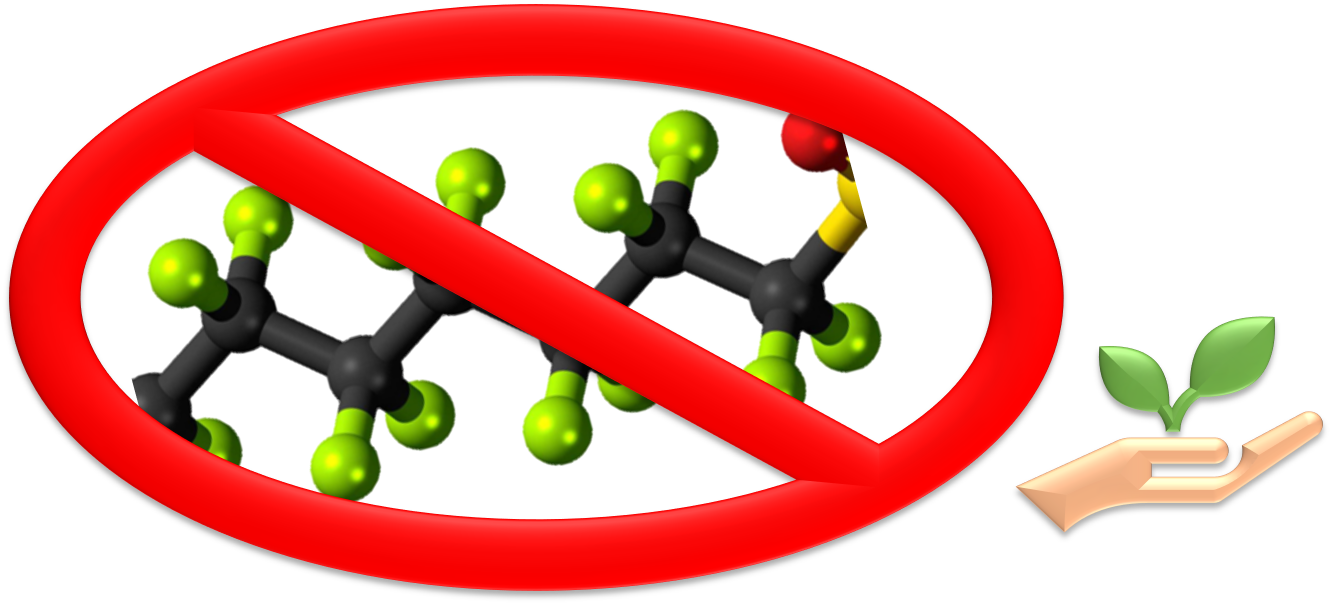

Seeking PFAS-free Low-Friction Coating for metallic cutting edges

Specific Technical Innovation Organization from European Union

Seeking existing market solutions targeted towards crawling insects

Ready to Market Technical Innovations and Products The Procter & Gamble Company

Seeking safe and effective outdoor mosquito solutions

Ready to Market Technical Innovations and Products The Procter & Gamble Company

Seeking technologies & expertise to improve the bioavailability of cannabinoids

Ready to Market Technical Innovations and Products Strategic Allies Ltd.

Seeking patents for license: DE, EP and US issued patents

Specific Technical Innovation CABIER INSTITUTE, SL